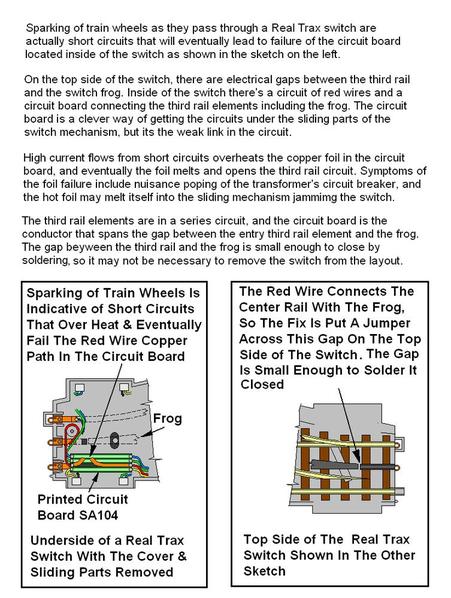

Hi, I am using MTH Realtrax on my railroad layout and a short while back I added a lead track to my small rail yard. The yard has a series of switches at each end creating ladders that connect to the lead track which then connects to the mainline. In order to do that a left hand switch was needed at one end to join the ladder to the lead track. I installed the switch, but in order to do that I had to remove a small bit of plastic off the roadbed base of the left hand switch. This allowed the left hand arm of the left hand switch to butt up to a right hand ladder switch. No big deal, but my having to do that made me think that MTH had not designed the switch for this particular application. With that said, I put the switch in place and wired it up so it could be activated by push button switch along the side of the layout. Everything seemed to work fine. No apparent problems until on evening I was running trains, smelled a foul odor and discovered that the switch I had just intalled had "fried". I had been running trains for pehaps 30+ minutes. When I took the back of the switch off I found that the red wire connected to a very thin metal strip that runs underneath a white plastic throw bar like mechanism and the strip itself had overheated and melted. I don't know what happened. What caused the red wire and metal strip to overheat to the point that some of the parts began to melt is a big question that I hope somebody can help me with. I am also asking for help to figure out how I can solve this problem as the left hand switch at this location is pretty critical to my making the lead track work. Below is a picture of another left hand switch so that you can see how the switch is wired. Any ideas/help would be very much appreciated. Thanks, Bo ![]()

Visit my website Bo's Trains at http://www.bostrains.com