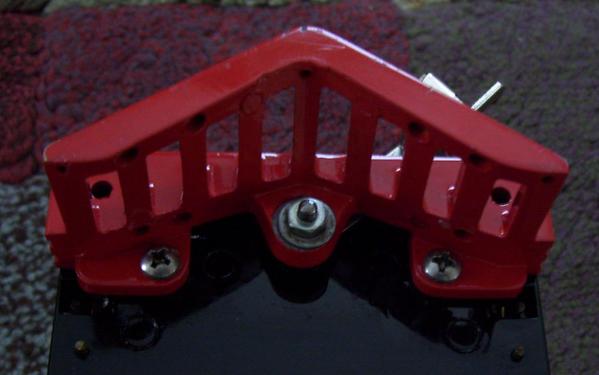

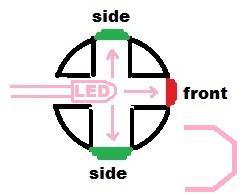

I have a Lionel Classics 390e and I never really liked the protruding headlight bulb. I replaced the bulb with an LED (not the screw in bulb replacements) and added a flat lens. It looks much better to me, but somehow, I think a convex lens would make it just right. Does anyone know where I could get a convex lens in the right size? I would also like to put tiny LEDs in the solid brass classification lights, but haven't figured out a good way to accomplish that. The classification "lights" also serve as a nut to hold the pilot to the frame. The brass "light" could be drilled out for tiny LEDs, but I can't figure out a good way to wire them. Any brilliant ideas out there?

Stan