Last weekend, I made a cheap little device that worked well, so I thought I'd share the idea on the 2-rail forum. I'm sure someone has already done this, but I haven't read about it before.

I needed to spread some 2-rail wheel sets, because the flanges were catching on switch points and guardrails (too narrow according to the NMRA gauge). Four of the wheel sets were in some unpowered, painted diesel units, and I did not want to bother with removing the microscopic screws that secure the journal retaining plates on their beautiful OCS F-unit trucks from P&D. Therefore, I wanted a way of spreading the wheels on their axles without having to remove the axles from the trucks.

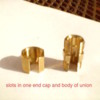

At ACE hardware I bought a small compression "union" designed for joining two sections of 3/8" copper tubing, then removed the ferrules and threaded caps at each end and cut a slot along the full length of the main body of the union wide enough to clear the diameter of the axle, all the way through to its hollow center. Next, I cut a similar slot through one of the threaded caps and replaced it on the union. With the slots lined up, the union and cap can be dropped over the axle. With only one of the compression caps in place, the overall length of the device is short enough to fit over the axle, between the wheels. Twisting the cap a little will allow the device to "capture" the axle.

Using two small wrenches, the union and the cap can be turned in opposite directions, causing them to spread apart and push the wheels into gauge. Even though it wasn't strictly necessary, I also added a washer with a slot cut into it so that it could also be slipped over the axle. I did this to maximize the number of threads engaged between the union and the cap. The 3/8" compression union is made of pretty heavy brass, so even with slots cut through it and through the end cap, there was no distortion and no slipping of the threads.

I was able to re-gauge all the narrow wheels on my A-B-B-A F-unit set in just a few minutes. Fortunately, all the wheels on the powered axles were OK, because this device clearly won't work on an a geared axle.