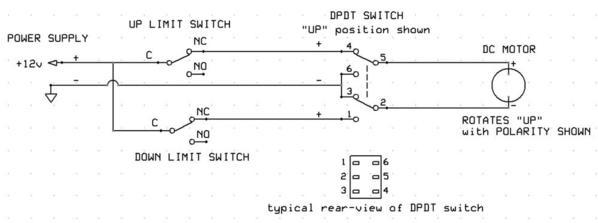

stan2004 posted:mike g. posted:...Stan if I just use a DPDT switch I would wire the limit switches just as before correct?I assume you are referring to your earlier thread about where/how to connect limit switches. Correct, nothing changes from before. From an electrical/wiring perspective the linear-actuator is just a DC motor as before.

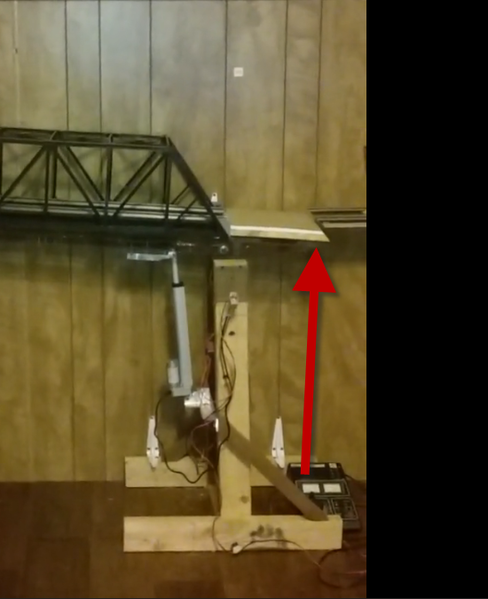

Thanks Stan, when the actuator arrives next week I will post some updated pictures.