In 2013 I posted a detailed description of the rebuilding my Pennsylvania & Pacific RR. This over 10 year saga covers all the details of building this railroad since that time. You can go back to the beginning with constructing the L-girder platform, laying over 300 feet of Ross track, building and wiring the control panel at this location on the Track Planning and Layout Design Forum.

https://ogrforum.ogaugerr.com/...-vs-old-build-thread

This railroad is on its third life. It was first constructed in Germany and was 21 X 13. It was built with the goal of disassembling and shipping back to the USA to our house in Bucks County, PA. I put it back together with an added 6 ft in length so it became 27 X 13 ft. After my early retirement from the housing industry in 2009, and our subsequent move to Louisville, KY, I modified it, and rebuilt it as a much larger, 39 X 15 ft railroad. I worked to eliminate all of the operational problems I had in the first two versions. The railroad is star-wired with 38 separately controlled blocks. It does not have digital control yet, but I wired it using home-run wiring throughout with high-capacity twisted pair wiring so it can get DCS whenever I'm ready to buy it. Meanwhile, it is a "Cab-control" layout run from both sides of a single-Z-4000 transformer. It has a separate DC power supply running the LED indicators for the block toggles and an interlock circuit that protects a swing-out door that permits access to the entire inside of the layout. In fact there are many DC power supplies running all the lighting. I'm using 100% LEDs now and find all of the old AC adapters laying around are a good source of DC power. I just bought my first purpose-built LED power supply to run all the lights in the new engine house. The age of the railroad, from its inception in Germany in 1999, speaks to the longevity of modern O'gauge equipment including 16 locomotives (MTH, Sunset 3rd Rail and one Atlas), Ross Custom Switches with Z-stuff for Trains machines, and the hefty MTH Z-4000 transformer, the newest of which is from 2002.

I noted when starting this thread that the layout was going to be fully scenicked, and it will be a big job that would stretch over years. Boy was I right! I've now been steadily working on it for over 10 years and have had some wonderful sub-projects that are defined in detail in this massive on-going thread. I had hoped that my eyes, hands and back would make it that far, and so far, with a couple of physical challenges creeping in, I'm hanging in there. Whatever you use most wears out first, and since I've been building models since I was 8, the hands are experiencing the most wear and tear. I am grateful for having most of the under-the-platform work finished since the back hasn't been happy either. When I built the layout the first time I was 24 years younger. My wife actually asked me if I was physically capable of the rebuild. I'm happy to report that I am and most of the injuries are temporary... I hope. At the time of this edit, I'm 78, and happily, I'm still building and still learning.

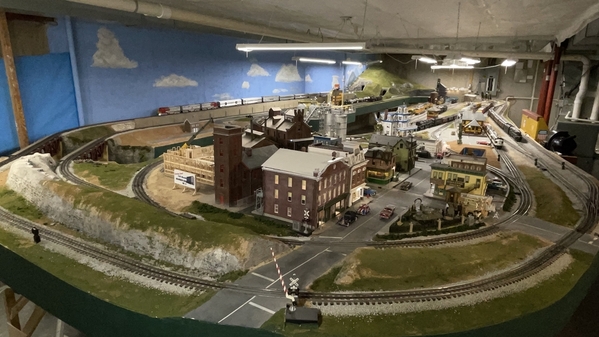

The layout has a large mountain with tunnels on one end and a the small town of Woodbourne on the other. In between are industries, yards and an engine service facility. I really don't have the room so there's no roundhouse or turntable, but there is a large engine house. The middle is open giving me complete access to almost all trackage without resorting to pop-ups (and more work under the table).

Here was my early rendition of the mountain region.

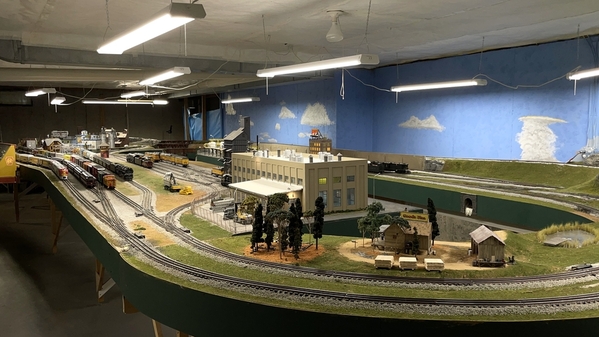

Here's a picture of the layout as it in Dec 2023. Included are the new engine house in the far background all illuminated with LED fixtures, the Hopper House, Heritage Park, the Bourbon rick house under construction and the Woodbourne Hardware House.

The bridges in the foreground-left are customized Plastruct Deck Truss Bridges and the third is a Deck Plate Bridge and they too, and all the beautiful ravine scenery is described here.

Lastly, throughout this massive undertaking there have been some signature projects that have found their way to the model railroad press with a substation described in the November 2015 Railroad Model Craftsman magazine, and a three-part article in the 2018 October, November and December issues of Railroad Model Craftsman on the design and building of a Victorian Bourbon Distillery that existed in Louisville, KY until Prohibition when it was razed. More buildings and articles are coming out of this very comprehensive thread. The Engine House is slated for publication and several articles have been submitted to OGRR.

So, if you're so inclined and have a couple of years to read about the trials and tribulations of big railroad building, please come along for the ride. I don't have all the answers. In fact, I have very few answers, so I expect my readers to be willing to give. And give you do. I get as much from my readers as I give, and many ideas, thoughts and plans came from them. I can point to many critical things that wouldn't have happened if it weren't for all the patient and attentive folks that read and commented on this forum. The articles wouldn't have happened. In fact, the buildings themselves may not have turned out as they did were it not for the support I constantly receive. Some folks that have been following this thread for years give me more credit than I deserve. You become a master of things by doing them a lot and practice. You have to start somewhere. The thought of starting is always worse than the actual journey.

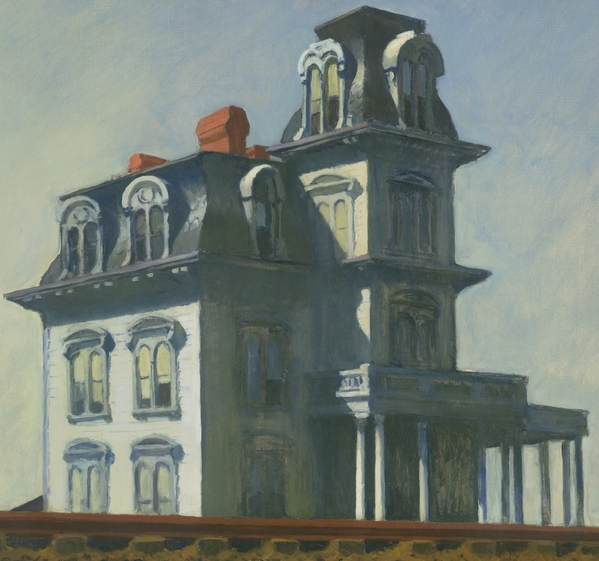

I am now fully engulfed in the world of 3D resin printing with the advent of the newest LCD Mask machines that have dropped the price on these amazing machines so normal modelers can have them in their shop. I've had some 3D printed parts done commercially, but now my capabilities have been greatly enhanced. I'm describing all the trials and tribulations going up this learning curve of a very new technology. A recent project is my rendition of Edward Hopper's "House by the RR" that has many, many 3D printed parts from my design.

The Hopper Original

The Hopper rendition "House by the Railroad" as complete, installed on the layout and the lights are on.

Hopper necessitated relocating the Idaho Hotel which required a new base and parking lot. Since then, I sold the Idaho Hotel to Mark Boyce where he's given it a nice home on his growing layout. I needed urban space for more of my custom projects. Then comes Heritage Park to fill the last oddly-shaped open lot on the layout. Heritage Park features 3D printed columns, lanterns, signs and entry arch. This starts on page 92.

And the railroad is undergoing a municipal improvement project with new street lighting and signage as seen in this night photo.

One last bit of downtown real estate is being filled with a bourbon warehouse (rick house) as it appears under construction. I chose to show it this way since, when finished, they're just a box with a bunch of windows in it. Under-construction is a whole different animal. You can view this build thread starting on page 95.

The Rick House is done and on the layout.

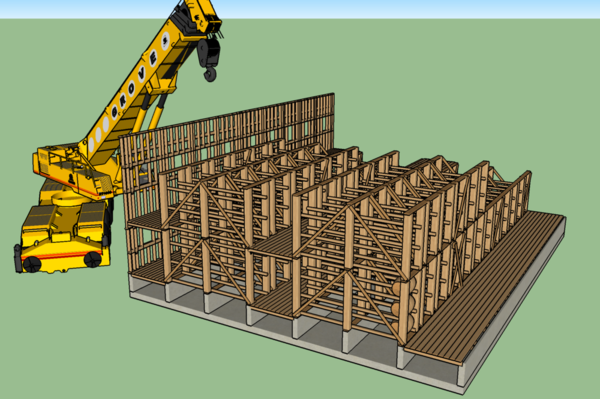

The next up is a model of the extant hardware store in Newtown, Bucks County, PA. Built in 1869, it's been a continuously operating hardware store since. In 1899 it burned down, but was rebuilt in almost original shape. Sometime in that period the owners bought the right side store and combined them into a larger hardware store. I'm doing it with some interior. The upstairs are apartments so I will not model them. All I did was compress the length a bit to fit in my layout space. This it the SketchUp drawing used to both create 3D models for the architectural details which I 3D printed, and the flat design drawings used to laser cut the flat parts. Construction has started and can be found on page 103.

The O'scale Hardware Store is in place, but there's still interior work to be done. None of my buildings are permanently attached to the layout. They're all on bases that are removable to facilitate repair, updates, or if required, sold.

Took a small side trip. With the success of the Hardware Store, the owner of the real store in Newtown, PA commissioned me to make an n-gauge layout to be used as a holiday store window display. I built such a RR with my grandkids when they were MUCH younger and commandeered it to be used to fulfill this job. I was able 3D print an n-scale version of the Hardware House and three other actual replicas of Newtown, PA buildings. It took some work to get the track into shape so it would run unattended, and I'm in process of finishing it up. Story starts on Page 107. The n-scale version looks just like it big brother...

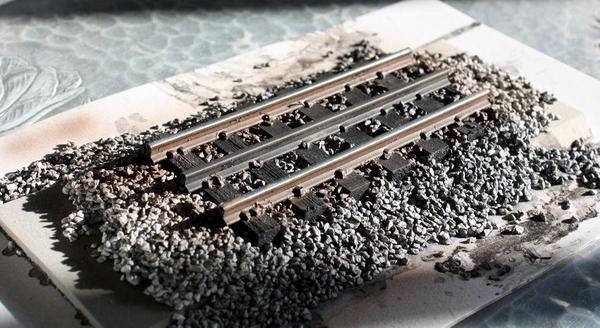

So So sit back, grab a cuppa Jo, and start reading. The Saga begins with ballasting 350 feet of track...