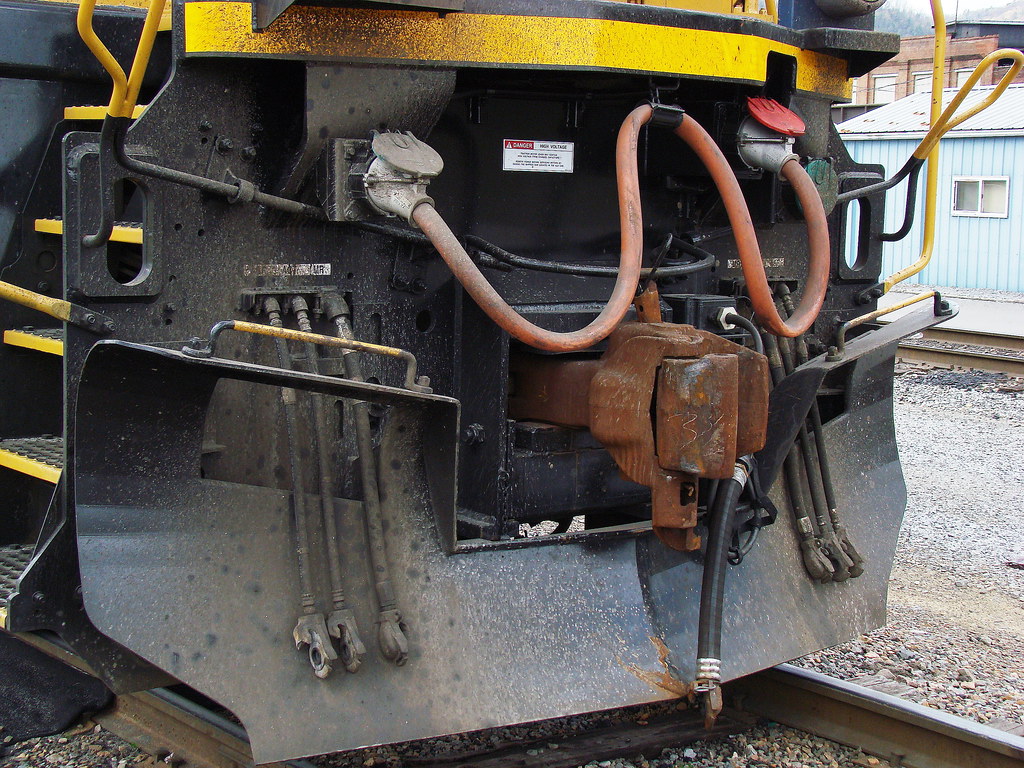

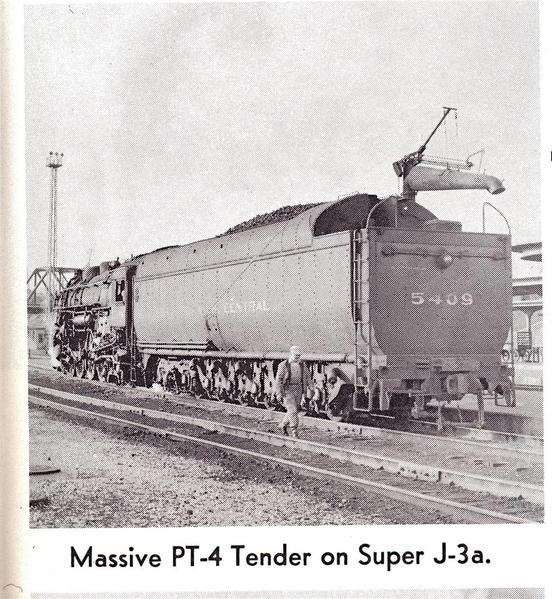

I was wondering if coupler lift bars ever pushed up the release pin from below rather than the more common lift up from above? Reason I am asking is I am repairing a NYC PT tender and the brackets for the lift bar are below the coupler. I can't find any pics taken directly from the back of this tender and all the models I have have the bars cut short to allow movement of lobster claw couplers. I can imagine a bar being bent up and then over the coupler but would like to know for sure one way or the other.

Anyone with good pics of the rear of a PT tender would be appreciated.

Pete