Guns,

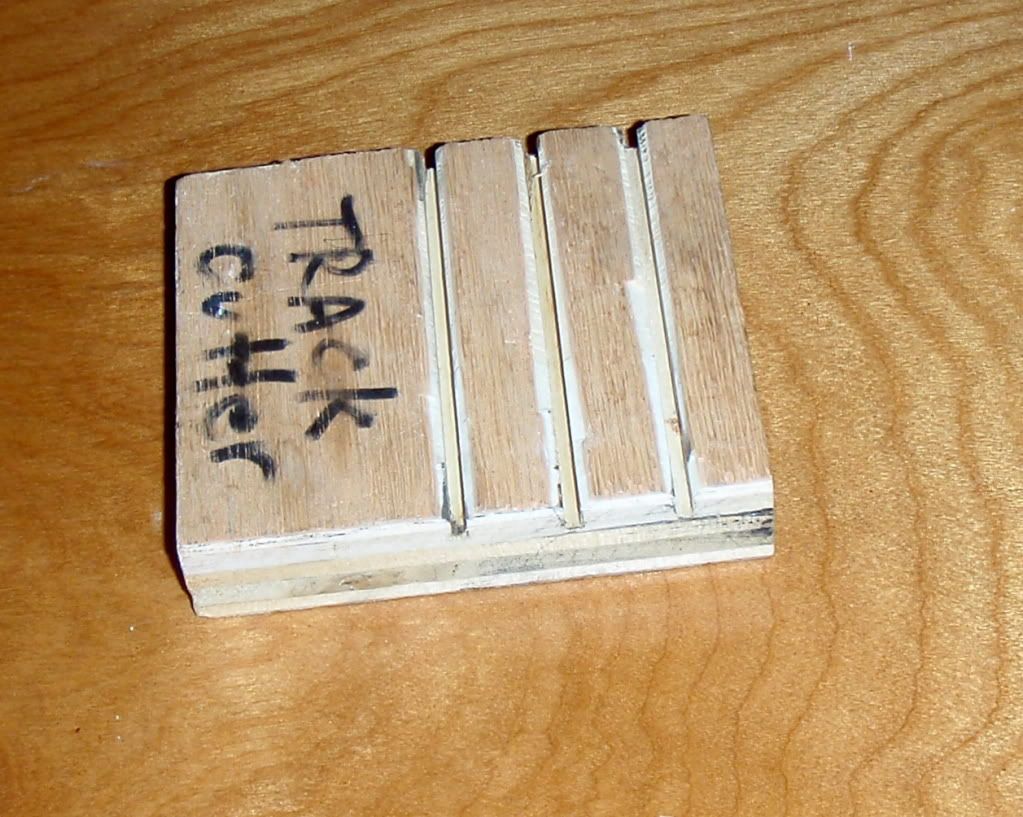

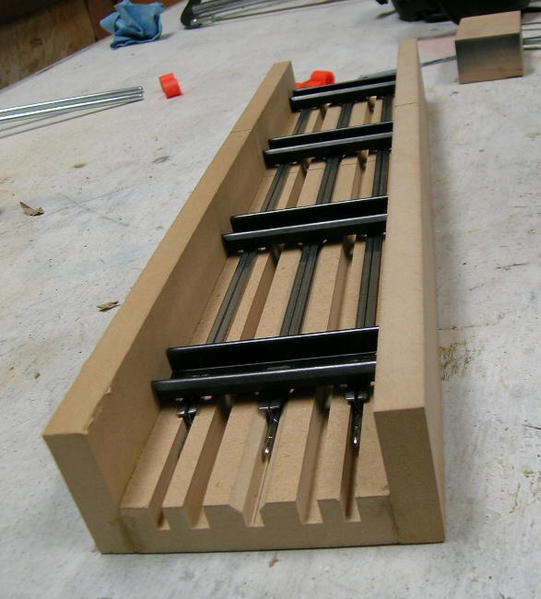

You bet and I also reuse the newer type slide pins by removing them from the piece I am cutting off and reinserting them in the custom cut piece I have just made, the new Kobalt Micro Diamond & Carbon File Set, makes this work with my high speed, a precision finish job. I wish they would have come out with these new quick coupling files around Thanksgiving time, instead of waiting till after Christmas. All in all when you have the correct tools and cut on a slight angle, the job comes out quite nicely.

A used FT CC switch I purchased new came in with some damage, I repaired the switch in the same manner I make custom track pieces, stealing the slid pins from a cut piece of Fastrack. Worked like a million bucks, in fact you can't even see where the repair to the front end of the switch was made now. As the Cajuns say, Much more better than good!

PCRR/Dave

In the lower right hand corner of the picture, you can see the custom angled track join, where the track rails meet the custom made, end of the repaired switch.