Paul,

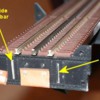

I made three lift up gates, two double track and one single track, using a 3/4 inch pine boards of two different widths for the double and single track lift up gates and two top mounted strap hinges to pivot the gate upward slightly over 90 degrees to stay open.

One hinge leaf of each pair of hinges is mounted to the lift gate the other other leaf to the stationary train board. The non-hinged board end bearss on a 1" by 2" wood strip, the 2" dimension is vertical. The stationary tracks either side of the lift gate and the track mounted on the lift gate must be in alignment and level also allow a maximum of 1/16 inch gap per end or 1/8 inch when the wood is cut for the lift gate, if the open width is 36 inches between the stationary sides cut the lift gate 35-7/8 inches long.

Once the tracks, stationary and lift gate mounted, are level and in alignment mount the 1" by 2" wood strip to the stationary benchwork opposite the hinged side and below the free end of the lift gate with wood screws. Mount the track to the lift up gate and four 1/2 inch thick by 2 inch long wook strips for mounting hinge leafs on the lift gate and stationary framework, mount each hinge to their respective wood blocks, the hinge pins should be located over the 1/16 inch gap between the lift gate and stationary framework. Secure the hinges to the lift gate and stationary framework, lift upward to open position, check for binding and track interference on lift gate track.

Next drill a 3/16 inch or 1/4 inch hole through the lif gate board adjacent to one of the outsge common rails this is for routing the wire leads that are soldered to the common outside rails and the hot center rail. I used 18 gauge solid insulated wire 6 inches long for these leads, one end of each wire was soldered to one rail the opposite stripped end was butt connected to 16 gauge stranded wire approximately 18 inches long. The free ends of these wires were routed through a 1/4 inch drilled hole in the stationary framework below the hinged connection. Flexible standed wire will basically fold up when the gate is closed and unfold when the gate is open to over 90 drgrees. The 18 gauge common wires were soldered to the 12 gauge buss wire and the 18 gauge hot wire was soldered to 12,14, or 16 gauge wires routed to powering toggle switches.

If you allow enough width outside of the hinge leafs on the lift board, you can add vertical griders made out of basswood and disguise the lift gate as a girder bridge.

Regards,'

John