After searching for awhile I found a bunch of threads about using foam sheets to form mountains but not much about the spray foam from a can.

I decided to give it a go, and being 3/4 of the way done, thought I'd start a thread about what I've learned so far.

I started by making a lattice of cardboard strips. This gave me my general shape, and let me build my tunnel over my existing track position.

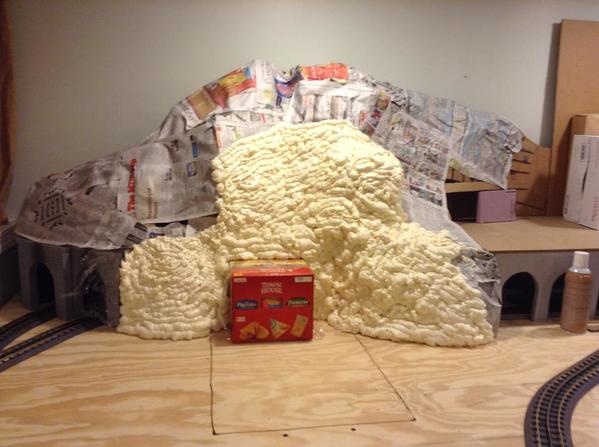

Because of the stickiness of the foam, I decided to cover the latticework with newspaper, held in place with some adhesive spray. This was to help ensure that as I was laying down the foam, none fell onto the tracks below.

The he red box in the middle is blocking a access area, in case I need to get into the mountain for any reason.

I covered the box, and the tunnel portals with plastic wrap, so the foam would not stick to them, but mold around the shape.

Next step was to lay the foam. I just started working in zigzag lines back and forth, from the bottom up.

This is approximately 1- 12oz can worth. So back to my local home improvement store to stock up. I picked up 5 ,ore 12oz cans. They do sell it in 24oz size as well, but the bigger can costs as much as 2 1/2 of the smaller ones (maybe they think carpenters don't do math well?)

I did this first section on Saturday morning and then got the rest covered that evening, so this section had a head start on drying.

Sunday, I was ready to try to add some shape.

I had adjusted my plans and decided to put the power pole over on the left side by the window. The lattice was not shaped for that flat area, so I built it up with foam. (HERE IS A KEY POINT: if you are going to build in layers, let the first layer dry completely before adding additional foam. I didn't do this, and I'll show you the result below.) I trimmed the bottom off the box I had used to cover my access and then inserted it back and filled it with foam.

Anyways, a super sharp hobby knife will cut through this stuff pretty good. My wife's clay carving/shaping tools on the other hand, not so much..�� Now, this stuff dries pretty smooth and round on the outside, and mountains don't look like that so I started to carve. In the middle I have a "blister" that I specifically want to be a nice outcropping of rock. I saw that as I started to remove the "round" it was also taking away the shape. Time to come up with plan B.

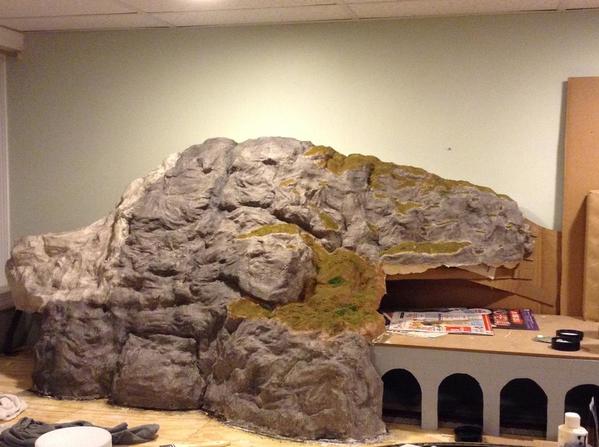

Plaster Cloth! I can get some good angles out of that and get rid of all the roundness. So Sunday evening, I start laying plaster cloth on the top. I got the "just dip in water" kind. I wore gloves, held the sheets over my bucket to let some of the excess water drip off (both tips I read about on here!) and went through my roll. It was clinging tight to the foam, and looking pretty good! The seams worked well into each other and weren't noticeable at all.

I had to get some more cloth, and ran out to the craft store last night, I had 2- 40% off coupons.