Over on the electrical forum, under a thread on removing slide shoes from operating cars, PLCPROF mentions he uses a type of fuse in feeds to uncoupling tracks, with a rating of less than current draw, that opens after a few seconds. He didn't provide more details.

A current sensor can also be used in the feed to uncoupling controllers, to open after a few seconds. I put together such a prototype circuit, but haven't gone further with it.

Landsteiner, there are few problems that can't be solved with enough money. It would cost a fortune to cut into walls and ceiling of an average home to install a sprinkler system, and if it were made mandatory, many homeowners would lose their homes through mortgage default. Changing building codes to require sprinkler systems in new construction is easier. Fairfax County Virginia has such a requirement for townhouses.

I note that many persons don't have operating smoke detectors, which are cheap enough. Putting one in a train room is not a bad idea.

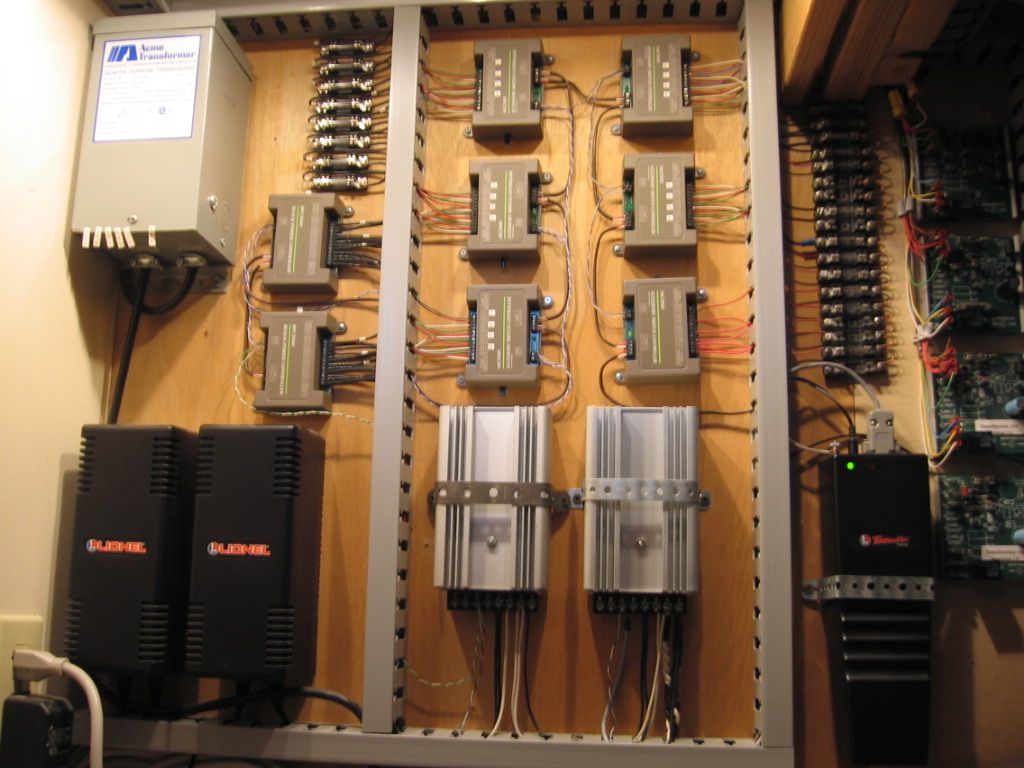

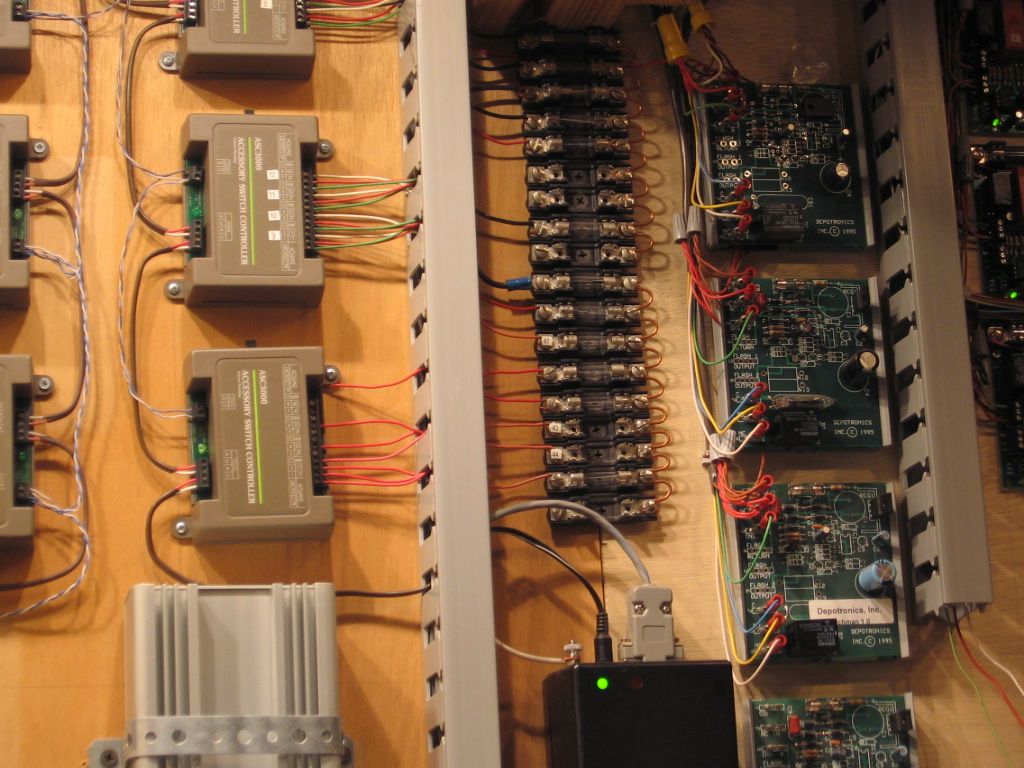

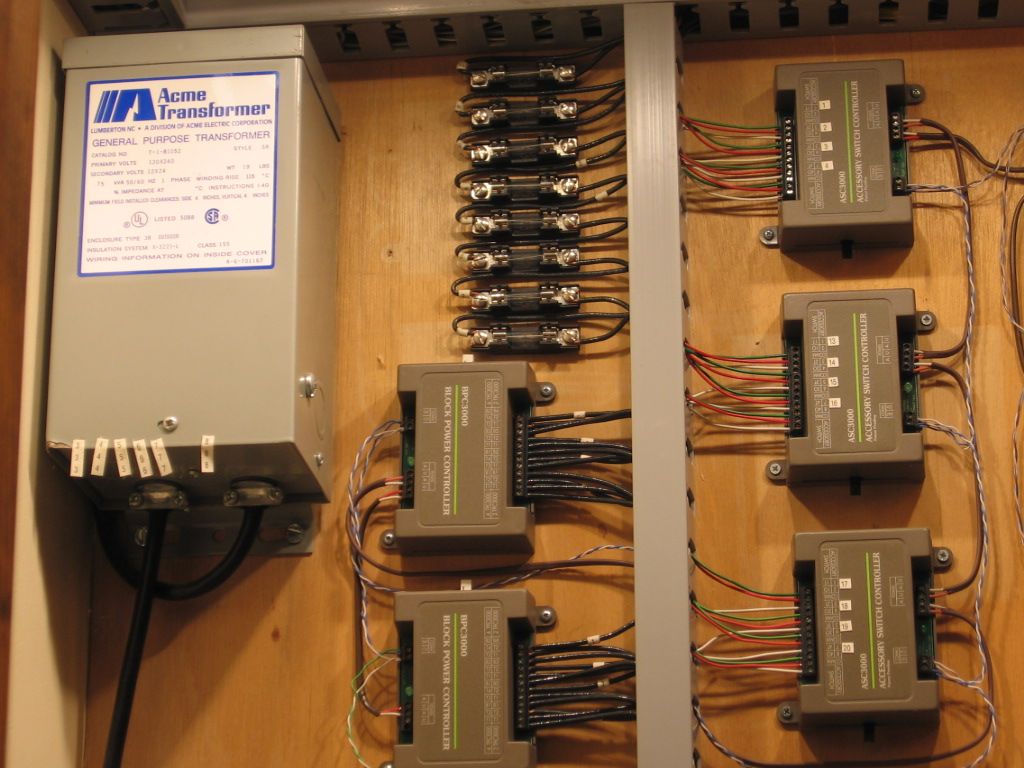

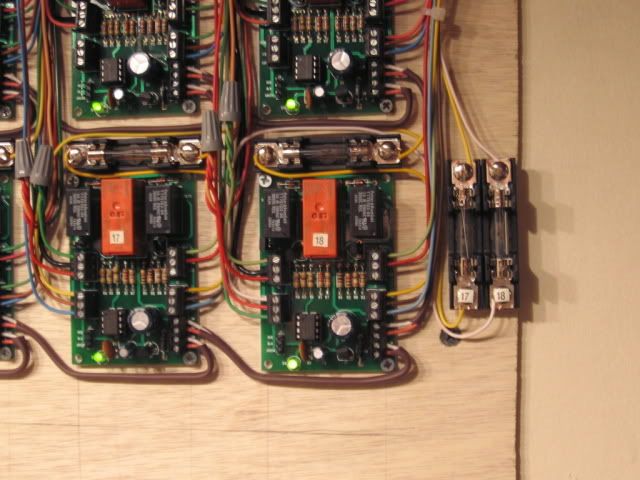

Reading some of the other posts above, not using smoke and having converted passenger cars to LEDs,, I find 5-amp breakers on most track circuits, and 7.5 on the one that often has 3-4 trains running, is quite enough. I also question whether any layout needs 20 amps available on the tracks. If one is running many trains, it is better from both an electrical distribution and a safety perspective, to have multiple blocks with circuit protection on blocks rather than on only "power districts."

The point about putting breakers or fuses on accessory circuits should not be overlooked. Over the last 70 years, I've had a few shorts.