Does anybody have a supplier for aluminum sheets that can be cut and bent into shape to serve as a heat sink and hold PS2 and PS 3 boards to the engine frame? I am looking for a square foot flat piece of machinable, thin, soft aluminum. I would prefer a business that advertises through our host. Sincerely, Hank

Replies sorted oldest to newest

Try any hobby shop, or try Lowes or Home Depot for thin aluminum strips. They come is 1/2" or 3/4" (or wider) width and in various lengths & thicknesses. They also have some sheets. There is, of course, no shipping charge.

Home Depot has flat bar aluminum stock.

The thicker it is, the better it will transfer heat from the electronics.

True, but harder to bend. No one is sure just how much heat is generated.

I used a 1" piece of 16 gauge solid copper Romex wire to secure the heat sink to the chassis in the Dreyfuss. It worked fine.

Don't forget heat transfer compound. It makes a huge difference on getting temp changes out of components faster by filling air gaps.

Mistakes? Wrong type? Wrong bend?

Heat the "worked" aluminum(hardened by work/machining) with a propane torch enough "to cook on", & then a little bit more, to soften it for cold bending after.

Without doing this fresh for each bend or re-bend, the aluminum will break and split when bent, much sooner, and easier. Too hot and it will flop/warp/deform.

I like that thick copper to the cold chassis trick![]() (copper draws/moves heat really well)

(copper draws/moves heat really well)

There was an instance where I used a computer ram heatsink cut down because I had nowhere to bolt the aluminum to the frame

I bought .064" aluminum sheet, I make my heatsinks from that. It's also handy to make mounting brackets for fan driven smoke upgrades. ![]()

One tip, when you're bending the aluminum, heat it up with a heat gun at the bend point first, then bend it. It'll not only bend easier, but you'll have a cleaner bend.

I repurpose 5V and 3V heats sinks. The only heat sink I had to make was a double stack to mount a PS-2 and Slave on top of each other for a Veranda Turbine. G

Check your local hardware store or Hobby Lobby for availablility and gauge thickness.

Thank you guys! Will follow all of the advice.

Thank you guys! Will follow all of the advice.

Aren't you going to end up with a lot of different heatsinks? ![]()

![]() Maybe you should pick one or two to follow.

Maybe you should pick one or two to follow. ![]()

McMaster-Carr will have aluminum in may types, shapes, and sizes.

Sorry I can't suggest which one is best for your application.

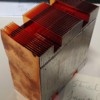

I have used the copper material from old computer processor heatsinks in the past. I get the older high speed processor ones which are a solid copper base with brass fins or solid copper fins. The normal processor heatsinks will be all aluminum.

Its easier to cut, drill, or hammer into an odd shape.

Or if you can get old Intel Xeon processor heatsinks they are much larger and usually have brass fins.

A home blowtorch can be used to separate the fins from the thick copper slab base (already separate in the pic). The larger and more conformed your contact area is to the engine frame, the better your heat will dissapate. A tight mechanical bond, two or three sscrews, will improve the contact surface. I would clean off any paint on the engine frame or surface, since this will be a slight insulator to the heat transfer. An extremely thin coat of processor heatsink compound between your "heatsink" material and the engine chassis will slightly improve the transfer. The thinner the compound the better. You can even use the old style suntan blocker (zinc oxide).

A home blowtorch can be used to separate the fins from the thick copper slab base (already separate in the pic). The larger and more conformed your contact area is to the engine frame, the better your heat will dissapate. A tight mechanical bond, two or three sscrews, will improve the contact surface. I would clean off any paint on the engine frame or surface, since this will be a slight insulator to the heat transfer. An extremely thin coat of processor heatsink compound between your "heatsink" material and the engine chassis will slightly improve the transfer. The thinner the compound the better. You can even use the old style suntan blocker (zinc oxide).

Attachments

I usually remote mount the bridge rectifier directly to the die-cast chassis or lead weight eliminating the whole aluminum bracket affair...and doing that reduces the overall mounting height.

I usually remote mount the bridge rectifier directly to the die-cast chassis or lead weight eliminating the whole aluminum bracket affair...and doing that reduces the overall mounting height.

Unfortunately, to do that with a PS32 board, you'd have to stand the board on it's head. ![]()

Any reason why the rectifier can't be completely severed from the board by cutting its leads in their centers, and connecting the stubs with 4 wires?

If you keep the leads reasonably short and use at least #16 or larger wire, I'm sure it would work fine. 3-4" wouldn't be an issue for the extension.

K&S Precision Metals has an assortment of different metal products that may work. At one time you could find a K&S display at most hardware stores and hobby shops. I've used a lot of their brass rod/brass products.

I bought my aluminum sheet from K&S as it happens. ![]()

Note that a lot of times you will find white grease compounds between electronic components and heat sinks, that is suppose to enhance the heat transfer.

If you keep the leads reasonably short and use at least #16 or larger wire, I'm sure it would work fine. 3-4" wouldn't be an issue for the extension.

Why so short? Both Lionel and MTH do this for the rectifier. MTH for the 1 Gauge. G

I like to remain conservative, if I don't specify anything, someone will try to remote them by three feet. ![]() Besides, there isn't really a need to make them really long.

Besides, there isn't really a need to make them really long.

Hard to get 3 feet in a 14" engine? ![]() Usually you need to get the rectifier to an open area to chassis sink it. Which is why I think Lionel does it in steam I have seen. Besides the advantage of the heatsink size. G

Usually you need to get the rectifier to an open area to chassis sink it. Which is why I think Lionel does it in steam I have seen. Besides the advantage of the heatsink size. G

Critical to this discussion, but totally unsaid, is any facts about how much heat the rectifier actually generates. Over the years, I have bought many rectifiers that included no mention of a need for a heat sink.

They are made to be surface mounted for cooling, and they get very hot without one.

I think by design it can handle it for a bit, sure. But what's the temp given in the lifetime duty cycle expectations?

Extreme changes in thermal forces can win out over a pieces integrity sooner.

I.e. Cracks, crumbles, burn away, separation of non metal regulator structure and even fire, is all less likely.

A steady thermal should give better performance in electronics as a rule of thumb..

Effecting other components, or even melting of something else is another consideration.

A cramped loco doesn't supply the free flowing air of a bench either.

The chips that really need it bad, usually come with it..

It's like buying the "tow package" on a car or truck.

Better cooling= less likely to fail.

Adriatic, I agree with all you have said, except the first sentence, since many of the rectifiers I've bought are not conducive to flat mounting.

Adriatic, I agree with all you have said, except the first sentence, since many of the rectifiers I've bought are not conducive to flat mounting.

Touche! ![]() That seems to be the case

That seems to be the case![]()

Critical to this discussion, but totally unsaid, is any facts about how much heat the rectifier actually generates. Over the years, I have bought many rectifiers that included no mention of a need for a heat sink.

When running on the bench for a spell with a bit of a load on the motors, using the PS2 3V board without a heatsink, the rectifier will get too hot to touch. When I measured one, it was running at 65C. That's in open air, running one motor, with a bit of friction to simulate a load. That's way too hot to run without a heatsink with a loaded consist and two motors being driven. The rating of those PS/2 bridge rectifiers is established with a proper heatsink. Look up the rating for any rectifier that has a decent current rating, you'll see the difference between performance and capacity with and without a heatsink.

Temp range is just one of those listings I think folks would tend to skip over unless doing design.

I know 65c(145ƒ-ish) sounds about right to me, but I've never measured one.

(now I have a new "target" for the IR temp gun![]() )

)

At 160-180f I'd be thinking about liquid cooling![]()

John, I figured that if anyone had done some research, it would be you. Thanks for some real data.

I don't know how long you ran the engine, but when I test PS-2 5V and 3V on the bench with a motor and heater I have never been burned by the rectifier. Current flow is limited to DC current needed less the diode voltage drop, so it is not like a linear regulator where the excess current is wasted as heat.

With smoke on and all lights of a diesel and 2 motors your normally under 2 amps on the AC voltmeter to the engine.

For the 5V board the regulator will burn you and it gets hot almost instantly.

Does it make sense to heat sink it, yes. You have to mount the board anyway. But I have seen other engines like S gauge where rectifiers where not sunk, just the FET/TRIACs. G

I hadn't thought about it, but I guess smoke unit current goes through the rectifier also.

Yesterday I had 3 12-car freights, 2 2-motored diesel and one steam, all with smoke off, running on my longest "loop." The Z4000 ammeter hovered about 3.0; I cannot vouch for its accuracy. It's amazing how little current these can motors use compared to the old Lionel motors from the '50s.

Since sensitivity to heat differs among fingers, the IR gun is really the only reliable method. But then you have to run loco with shell off unless you have a test board.

In comparison I had a PW Dual pulmore GG-1 that pulled 2.5 constant, and had 4 amp peaks from a dead stop.

FET's don't drop much voltage, hence they don't get warm. Diodes, OTOH, do drop voltage and thus have significantly more power dissipation. I didn't say it the HS would burn you, 65C really isn't quite that hot. However, if you're drawing several amps through the rectifier, you have several watts of power being dissipated. It will get quite warm without a heatsink.