Only problem is it's not supposed to be coming from under the layout! ![]() I never had any burnt wiring of any sort on the layout, but that all changed last night. I had been running maybe 10 minutes, when suddenly there was that acrid unmistakable smell of hot burning insulation. Yikes! Shut everything down really quickly and started investigating. Smoke was pretty thick under one end of the layout. Eventually I discovered the culprit: About 2 feet of burned 22 AWG wire feeding a Lionel #195 floodlight tower in my main yard. It turns out that earlier in the evening I had knocked the tower over accidentally and I guess in setting it back up one of the wires became unclipped from beneath, and quite naturally shorted to the other wire clip. Some pix below.

I never had any burnt wiring of any sort on the layout, but that all changed last night. I had been running maybe 10 minutes, when suddenly there was that acrid unmistakable smell of hot burning insulation. Yikes! Shut everything down really quickly and started investigating. Smoke was pretty thick under one end of the layout. Eventually I discovered the culprit: About 2 feet of burned 22 AWG wire feeding a Lionel #195 floodlight tower in my main yard. It turns out that earlier in the evening I had knocked the tower over accidentally and I guess in setting it back up one of the wires became unclipped from beneath, and quite naturally shorted to the other wire clip. Some pix below.

Here is what was left of the wire after removal:

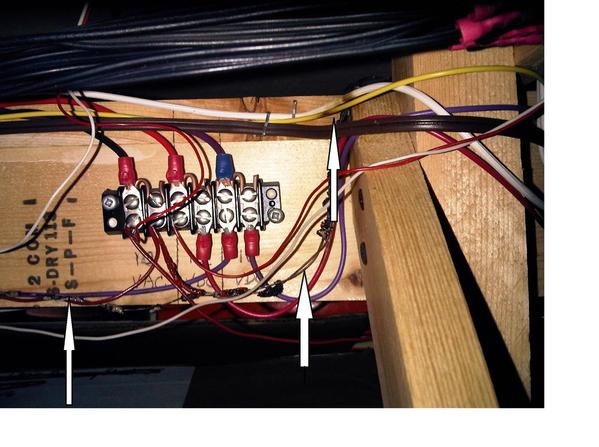

Here is the offending wire with arrows showing burned off insulation and peripheral damage:

Here is the base of the floodlight tower:

More of the wire before removal:

One wonders how much longer it would have been before fire might have broken out? And with all that wood and homasote around, well let's just say it would not have been pretty!

Now I am typically pretty careful about circuit protection, using fuses, breakers, etc as appropriate. But here is how this came to be, and it just shows how ca-ca happens. Years ago the few accessory lighting loads on this end of the layout were served by the 10 VAC output of a Z-4000, which has a 4 amp breaker. My rational at the time was that the CB would most certainly protect the main 14 AWG circuit distributors (to strategically placed terminal strips), as well as several smaller individual 22 AWG feeders to each of several accessories. Then as time went on and more stuff got added, pretty soon the 10 VAC Z-4000 output became overloaded. So I installed a 12VAC 400 watt outdoor lighting transformer to handle all 12 VAC accessory lighting loads on the layout. The entire circuit is protected by one 15 amp fuse right at the transformer, and the whole thing has been working really well for several years. Well, had I done even a token hazop thought process I would have quickly realized that none of the small individual 22 AWG accessory feeds would be adequately protected by the main 15 amp breaker, and this whole scenario could have been avoided. When the floodlight shorted out the load quickly over-heated the wire and burned the insulation off. After repairs I measured and found that the total load on the 12VAC transformer is 8.8 amps, so I have changed the 15 amp fuse to a 10 amp. And I am installing individual 5 amp inline fuse holders on all sub section 14 AWG distribution feeds, just so this won't happen again. Live and learn I guess! ![]()

Rod