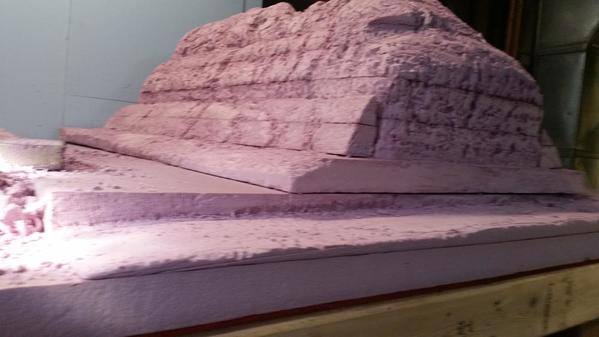

The only other tool I used was a soldering iron. I used the hot iron to get rid of the block look and corners. After I rounded it off, then I started cutting, sawing, etc.

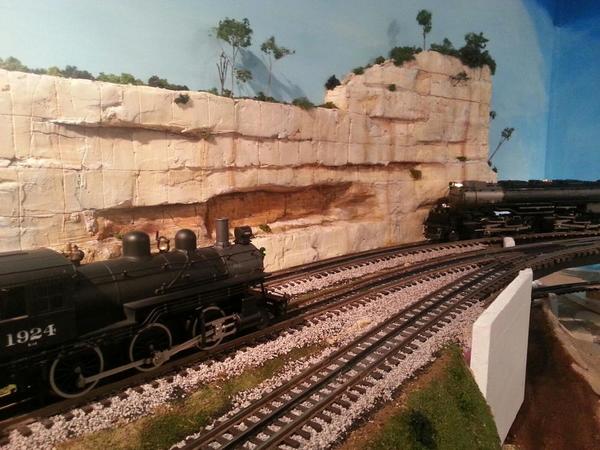

I started with a heavy medium grey. I love Home Depot and Lowes "Ooops" latex. Every time I go to those stores I buy whatever ooops paint they have in the samples or quarts.

Then I used brown. I would barely put the stiff bristle tip in the paint. Then I would dab the tip of the brush on the foam in 6 to 8 different areas. a few inches apart each. Then I would make hard and rough brush strokes over that area where I made the dabs. Any area that looks like too much paint I would brush and brush and brush very hard.

Then I repeat this with a light grey and then again with white.

Lastly I made some ugly looking very watery mud colored paint, water mix. I did the same technique as above but used light wispy strokes. When I got the look I liked, I dipped the brush deep in the water paint and then held it over the top of the rock (foam). It would drip and then run to the bottom taking a natural path. If the paint did not come of the brush enough I would get it FULL of water paint and dab it so the water paint would puddle and run to the bottom.

Hope that helps. Have Fun!

Ron