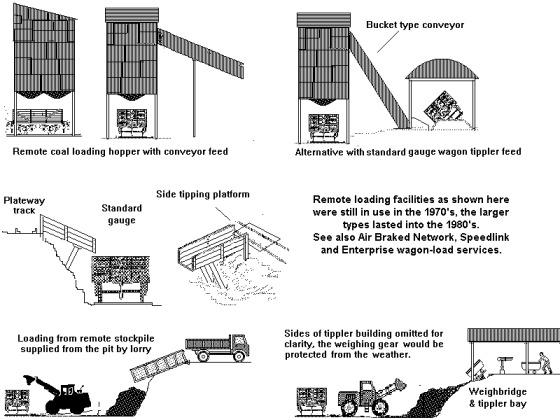

I guess folks have differing approaches to "figuring" what they want. For me I would start with research on what coal facilities really looked like to see if the prototypical designs provided enough architectural design elements that were interesting to me. If you want to be prototypical then you could chose your design that way. If those designs are too "whatever" for you, and you want a unique structure you could look at various architecture designs, elevations, details for buildings other than coal facilities. You could for instance think of a coal business that moved into an existing building and modified certain elements to suit the new purpose. This could be a really neat project. No rules (unless you want to be prototypical), just imagination. For me kitbashing is always a good option because the basic structural parts and details can be tailored to suit. Scratch building for the higher skilled or adventurous.

I did a simple modification on a lionel coaling building by just turning the brick part of the structure 90 degrees and relocating another part.

But I also experimented with an elevated coaling building with a trestle track before I redid parts of my layout scenery.

Good hunting.