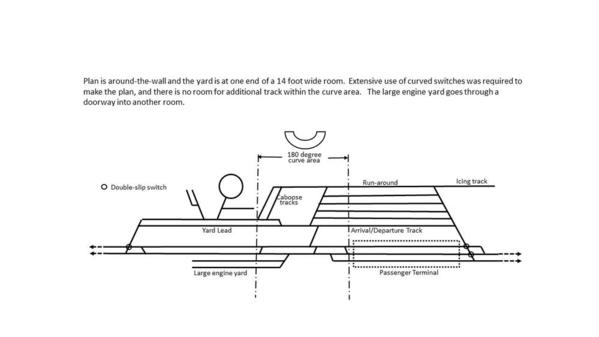

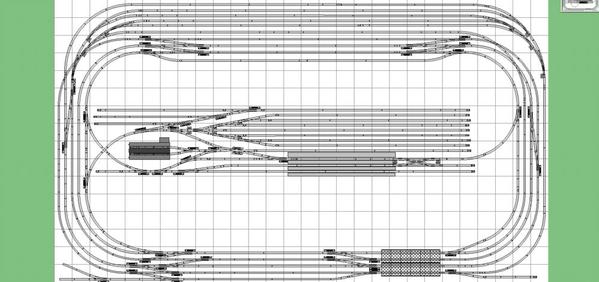

Here is a schematic of my yard design. The yard is at the end of the room and makes a 180 degree turn in the area indicated. Nearly all turnouts are O-54/#4 or larger. The arrival/departure track has O-72 curves so I can get my large engines in and out. I've used all the space available to get here, and I think I have captured most of the basics for somewhat realistic operation. I know there are a few problems, like the run-around track interferes with the yard lead to get to the turntable, but there is no room to add any more track in that area.

I would like comments on the design from those who have yards designed for realistic operation. If there is a critical flaw I missed, hopefully one of you will see it. If needed, I will do a redesign. Thanks.

Ron