Alan Hummel posted:WOW!!! Your layout benchwork is AMAZING!!!

Thank you, it's been a project but I'm very happy with it.

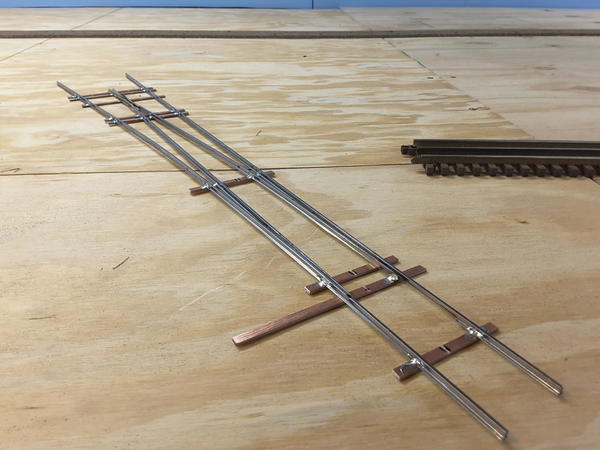

My total layout area is 25'x50',with 2'7" shelves in width on the north 44' run that will house my yard & a few industries. The shelf is 37&1/2" high from the floor. The east end has 2'5" wide shelves,same approximate height. I have about a 10' run of shelves 3' wide on the south end then it's water works,i.e. sump pump,water heater,etc.,then I have about another 16' run of shelves 3' wide finishing up the south wall. The shelves on the west end are 3' deep but I can only run about another 10' on that end as desks & furniture take up the rest of that run. So I plan about a 44' run on the north end of the basement,then make a 50' radius curve heading south. I plan to use the south shelf mentioned last for a short industry. The south shelfs will house something. I plan on making a straight run east & west that'll house mainline tracks. My basement's full,but I'll work "over" the obstacles as lumber becomes available.

Sounds like a good plan that should offer some really nice modeling.

My "thing" here in my area,is that it looks "cramped" compared to yours,Chris,and I thought you had a shorter area,correct me if I'm wrong. What am I missing? I'm trying to view my layout from my mind's eye while you have a table top laid out. 10 60' grain hoppers fill up a yard track & it makes me think O is going to look "out of place" in my area. Am I just being paranoid?

Paranoid?...No, it tells me that you're thinking. O Scale will definitely chew up space quickly and as such some "modifications" are in order. In my case I won't be running 100 hoppers full of coal with a Y6 and a Class A on the point with a Y6 pusher, maybe 30 hoppers on a good day...it will look the part. I don't think you'll have anything to worry about with your set up. If need be widen a shelf by a few inches here and there, play with the design a bit in relation to the operations you wish to have. My tabletop portion is for a bit of a yard and a engine servicing area and is roughly 30 feet long and about 6 feet in depth so it will work well. The overall length of the layout is 44 feet by 23 feet. I am also incorporating areas where I can expand in the future if I choose.

Al Hummel

![20170316_202600[412] 20170316_202600[412]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767780556313/fodoid/71819767780556305/imageType/MEDIUM/inlineImage/true/20170316_202600%255B412%255D.jpg)

![20170316_202605[411] 20170316_202605[411]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767780556314/fodoid/71819767780556306/imageType/MEDIUM/inlineImage/true/20170316_202605%255B411%255D.jpg)

![20170316_202619[413] 20170316_202619[413]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767780556315/fodoid/71819767780556307/imageType/MEDIUM/inlineImage/true/20170316_202619%255B413%255D.jpg)

![20170316_202628[414] 20170316_202628[414]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767780556316/fodoid/71819767780556308/imageType/MEDIUM/inlineImage/true/20170316_202628%255B414%255D.jpg)

![20170316_202600[412] 20170316_202600[412]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767780556313/fodoid/71819767780556305/imageType/SQUARE_THUMBNAIL/inlineImage/true/20170316_202600%5B412%5D.jpg)

![20170316_202605[411] 20170316_202605[411]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767780556314/fodoid/71819767780556306/imageType/SQUARE_THUMBNAIL/inlineImage/true/20170316_202605%5B411%5D.jpg)

![20170316_202619[413] 20170316_202619[413]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767780556315/fodoid/71819767780556307/imageType/SQUARE_THUMBNAIL/inlineImage/true/20170316_202619%5B413%5D.jpg)

![20170316_202628[414] 20170316_202628[414]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767780556316/fodoid/71819767780556308/imageType/SQUARE_THUMBNAIL/inlineImage/true/20170316_202628%5B414%5D.jpg)

![20170322_145031[561] 20170322_145031[561]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767918091899/fodoid/71819767918091890/imageType/MEDIUM/inlineImage/true/20170322_145031%255B561%255D.jpg)

![20170322_145050[562] 20170322_145050[562]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767918091900/fodoid/71819767918091891/imageType/MEDIUM/inlineImage/true/20170322_145050%255B562%255D.jpg)

![20170322_145100[563] 20170322_145100[563]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767918091901/fodoid/71819767918091892/imageType/MEDIUM/inlineImage/true/20170322_145100%255B563%255D.jpg)

![20170322_162245[558] 20170322_162245[558]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767918091902/fodoid/71819767918091893/imageType/MEDIUM/inlineImage/true/20170322_162245%255B558%255D.jpg)

![20170322_162258[559] 20170322_162258[559]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767918091903/fodoid/71819767918091894/imageType/MEDIUM/inlineImage/true/20170322_162258%255B559%255D.jpg)

![20170322_162306[560] 20170322_162306[560]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767918091904/fodoid/71819767918091895/imageType/MEDIUM/inlineImage/true/20170322_162306%255B560%255D.jpg)

![20170322_145031[561] 20170322_145031[561]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767918091899/fodoid/71819767918091890/imageType/SQUARE_THUMBNAIL/inlineImage/true/20170322_145031%5B561%5D.jpg)

![20170322_145050[562] 20170322_145050[562]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767918091900/fodoid/71819767918091891/imageType/SQUARE_THUMBNAIL/inlineImage/true/20170322_145050%5B562%5D.jpg)

![20170322_145100[563] 20170322_145100[563]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767918091901/fodoid/71819767918091892/imageType/SQUARE_THUMBNAIL/inlineImage/true/20170322_145100%5B563%5D.jpg)

![20170322_162245[558] 20170322_162245[558]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767918091902/fodoid/71819767918091893/imageType/SQUARE_THUMBNAIL/inlineImage/true/20170322_162245%5B558%5D.jpg)

![20170322_162258[559] 20170322_162258[559]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767918091903/fodoid/71819767918091894/imageType/SQUARE_THUMBNAIL/inlineImage/true/20170322_162258%5B559%5D.jpg)

![20170322_162306[560] 20170322_162306[560]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/71256347393343804/filePointer/71819767918091904/fodoid/71819767918091895/imageType/SQUARE_THUMBNAIL/inlineImage/true/20170322_162306%5B560%5D.jpg)