The wife has given permission for me to put an around the room ceiling/shelf loop in our bedroom. I have come up with a simple plan that'll allow for 2 trains to be up there, and we just pick which one to run. Problem is our AC vent would be blocked by the platform. The vent is near the corner, so if I make the turn into a bridge, then the flow of the cold air required for survival in the AZ desert will not be blocked. Does anyone know where I could get a bridge, or have info on building my own (Which I would love to do.) that will support the weight of and have clearance for a scale Big Boy while only being anchored at the two ends? Below is a SCARM plan of the room with the track. The black box in the lower right is the AC.

I'm thinking something like this, only curved.

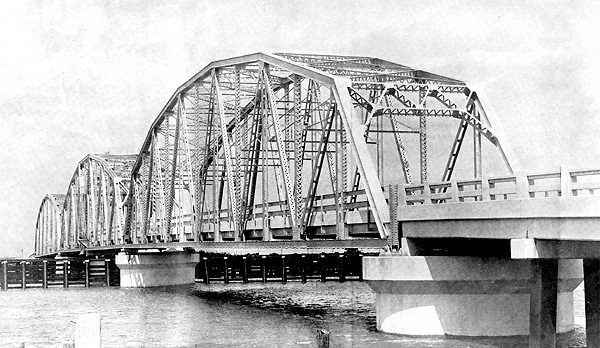

But a segmented bridge like this would be okay too if need be.