"Butch, as you know, I've done some with Kelly's frames and they are nice but the DesPlaines are heavier and cheaper. What am I not seeing here?"

Sorry, I can't find the quote icon so I'm doing it the old fashion way.

I still have two Des Plaines brass frames Jay, but liked the fact that Kelly's frame was stiffer. One of my DP frames has a bow and I figured it would change the shape of the plastic RC walkway rather than the walkway straightening up the DP frame. I also figured it might not be as stout as Kelly's frame going forward, which is mostly likely wrong. Actually both frames will work fine, but I wanted to try Kelly's frame and help his project to fruition.

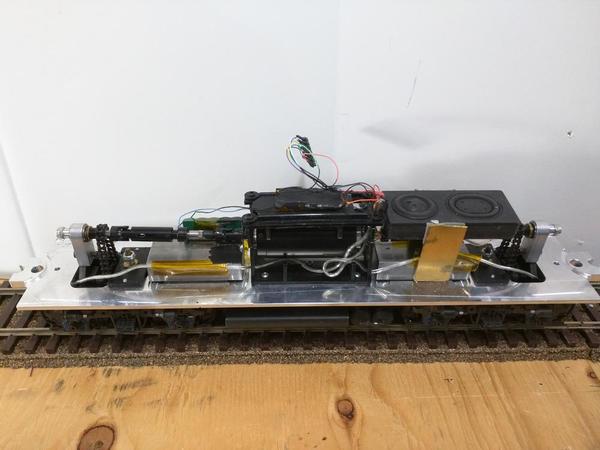

I checked the fit of the RC loco on Kelly's frame last night and I was totally wrong. Couplers will hold his frame to the walkway/shell very nicely, just like they do on the factory set-up. Very easy to do this.  I'm not sure what I was thinking, but I'll chalk it up to a senior moment.

I'm not sure what I was thinking, but I'll chalk it up to a senior moment.

I have enough decorated RC shell kits, purchased decades ago, that I can use the DP frames to make un-powered units. I won't need more than one powered unit per train on any layout I'll have in the future.

This thread has re-inspired me to get my a-- in gear and back on these projects. I love GP-9's almost as much as "F" units and have enough of each in the queue to take years to complete if I just get started.

Butch