The Prototype - Background & History

This layout is my attempt to model the 7 miles of the PRR Panhandle that ran through the northern panhandle of West Virginia and Steubenville, OH. The Panhandle was a second mainline of the Pennsylvania Railroad that ran from Pittsburgh to St. Louis. It existed from 1848 through 1995. Grif Teller immortalized the double track bridge across the Ohio River in the painting “Crossroads of Commerce” which appeared in the 1953 Pennsylvania Railroad Calendar. That bridge still stands and the track using it serves Weirton Steel (now Arcelor Mittal) and the brick refractories and businesses on the New Cumberland secondary. Unfortunately from Weirton Junction through Burgettstown and points east, the track has been pulled up and the right of way has been converted to a hiking / bike trail.

I grew up in Weirton, WV in the 1950s & 1960s. I left in 1978, but still have family and other ties in the area. The PRR double-track bridge at MP 42.11 was always a source of fascination for me, even as a small child going to Steubenville with my parents and grandparents. However, it was not until I saw Teller’s painting (in the late 1990s) that I realized what I wanted to model.

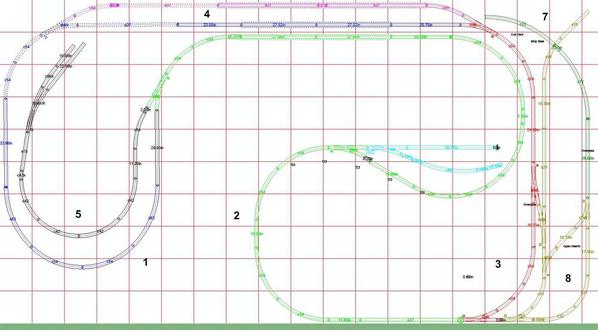

Vital Statistics of the Layout:

- Size & Shape: Folded dog bone - 8.5’ x 18.5’ x 10’ x 18.5’ – approximately 180 square feet. There is an 8.5’x 5’ hidden storage yard under the western end.

- Track: Mostly GarGraves with some Curtis sectional curves, Curtis Hi-Rail turnouts, and a few Ross Custom Switch turnouts.

- Yards: Weirton Junction, Weirton Steel, Coal Mine Spur, Hidden Storage

- Command System: TMCC. Turnouts have Z-Stuff DZ-2500A & C switch machines and are both TMCC and pushbutton controlled.

- Wiring & Blocking: 8 power districts are supplied from 2 power distribution panels. Home run wiring has been used.

- Power: 2 Lionel 180 watt PowerHouses supply all track power to districts 1-8. Two (2) K-Line PowerChief 120 transformers power switch machines, lights, and some AC accessories. All DC accessories, building lights, traffic signals and street lights get their power from various 3VDC, 5VDC, and 12VDC power supplies.

- Signals: Z-Stuff DZ-1060 PRR position signals (4) & MTH PRR signal bridges (2). The layout is only signaled for travel in the counter-clockwise direction.

Track Plan:

Districts are numbered and shown in their colors:

1 - Steubenville BLUE

2 - PRR Bridge & Weirton LT GREEN

3 - Weirton RED

4 - Hidden Passing Siding MAGENTA

5 - Coal Mine Spur BLACK

6 - Weirton Junction LT BLUE

7 - Hidden Storage Yard GREEN

8 - Weirton Steel Yard YELLOW

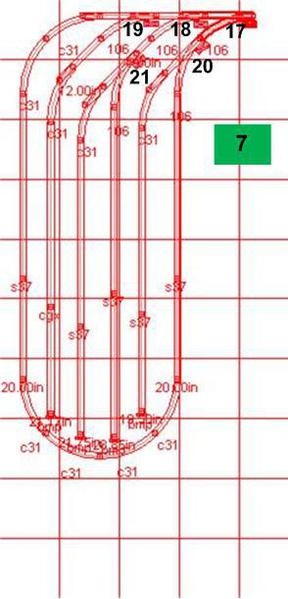

Hidden Storage Yard:

This yard is reached by a long yard lead below the rear of the layout. Storage is available for approximately 40 cars on 4 stub tracks. A balloon track is available for turning trains. The yard will permit Weirton Steel to accept arriving deliveries (coal, ore, empties) and ship product (coils, boxcars, empties).

Features of the Layout’s Western End:

Steubenville, Ohio dominates the western end of the layout. The center of the action is the intersection of Fourth and Market Streets. Fourth Street runs roughly east to west. Market Street will contain some of the nicer businesses, including a 5 story building. The west end of Fourth Street will be the "wrong" side of the tracks. There will be a seedy hotel and other run-down structures in this area.

The PRR station will be at the south end of town with the platform between the spur and mainline.

The coal mine and tipple just north of Steubenville supplies coal for Weirton Steel. The 2-track tipple can load approximately 4 cars at a time. The tipple spurs have been extended by several inches to accommodate track bumpers. A curved #6 Curtis switch allows the spurs to bend around towards the northeast. These tracks sit (level) on top of a plateau about 1.5” above Steubenville (behind Market Street). The coal mine is reached by a trailing point spur that allows coal trains to be backed all the way up to the tipple. The spur is protected by a Pennsy 3-position signal head.

The Gould No. 5 tunnel passes under the coal mine and exits just before reaching the Ohio River Bridge. Within the tunnel, a turnout connects to the hidden passing track that runs behind the screen and river bridge. This hidden track allows trains to cross the river without being seen.

Features of the Layout’s Eastern End:

The dual-track bridge is 7’ long and was supplied by East Coast Enterprises. Originally, I had planned to build the bridge myself, but it proved impractical time-wise as well as prohibitively expensive. I erected a temporary bridge that held a Curtis double cross-over, but I removed that when the permanent bridge was installed. The bridge is protected on both ends by a pair of MTH PRR double-head signal bridges. The southernmost track is for eastbound traffic, while the other (northern) serves westbound movements. East of the bridge (as the track loops back on itself and moves west) is Weirton Junction.

Weirton Junction is protected by a Pennsy 3-position signal head and will eventually sport a replica of the prototype WC PRR Interlocking Tower. One track will be designated as Standard Slag, allowing Lionel and MTH slag cars to park here and discharge their slag loads. These tracks will also serve as an engine pocket for the WSX Alco S-2 switcher as it moves ore car cuts in and out of Weirton Steel. The track may also end up storing cabin cars.

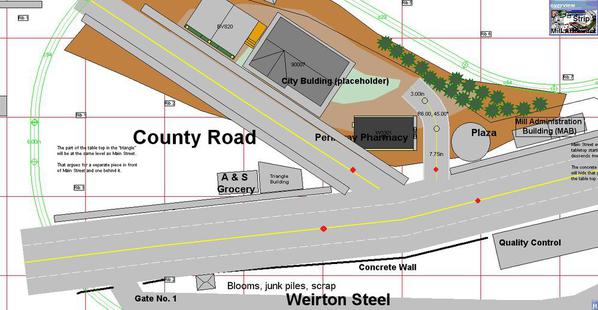

The city of Weirton will be the center of the layout’s eastern region. Depiction of the city will focus on the appearance of North Weirton in the 1950’s. The Green Mill Restaurant (although it existed as a family business during the 1920’s and 1930’s) will be located here, just across Main Street from Gate No. 1. The mill wall will parallel Main Street to the intersection of County Road and Pennsylvania Avenue.

Downtown (North) Weirton at the intersection of Main Street, County Road, and Pennsylvania Avenue will feature several unique structures - the Triangle Building, Weirton Steel's Mill Administration Building (MAB), the Quality Control Lab (QCL), and the Honor Roll (a memorial for members of the armed services). Working traffic lights will control the intersection and lighted telephone poles will illuminate the streets throughout the downtown area.

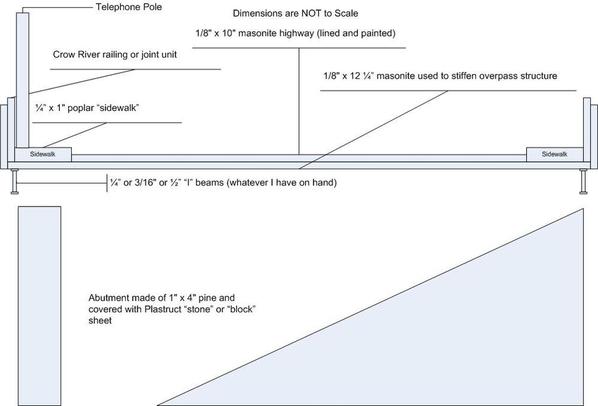

At Crawford's Crossing, Main Street will ascend a highway overpass bridge over the steel mill yard, just as in the prototype.

Weirton Steel:

Another major feature of the layout is Weirton Steel. The company’s mills are located against the eastern wall of the layout. The steel mills fit into the wall at a 30 degree angle. Mill buildings and items considered for this area are (south to north):

- Open Hearth: This mill has 2 industrial smokestacks. Ingot (flat) cars will move in and out of this mill. This building will disguise a descending spur to the hidden storage yard. (Built)

- Blooming Mill: This will also be a vertical channel black steel building with a WSX Logo on front. A billboard will be placed on the front. A raised transformer platform will sit at the side of the mill. (Built)

- Strip Steel: This will be the largest of the mill buildings and will have a spur running into it. The spur will be used to bring in empty gondolas (exit with pipe and coil loads). (Under construction)

Other structures that will be part of the mill will be a tank storage structure, floodlight towers, and a coil yard.

Operational Goals:

The PRR Panhandle was developed with the following operational goals in mind:

- Allow the simultaneous operation of at least 2 trains on the mainline and 2 switchers in yards or spurs.

- Use a signaling system that prevents collisions.

- Have curves large enough to permit the use of 72’ scale heavyweight passenger cars (requires at least O42).

- Allow the use of medium-sized PRR steam locomotives (requires at least O54).

- Permit the running of long trains (10-15 hoppers or 6 passenger cars).

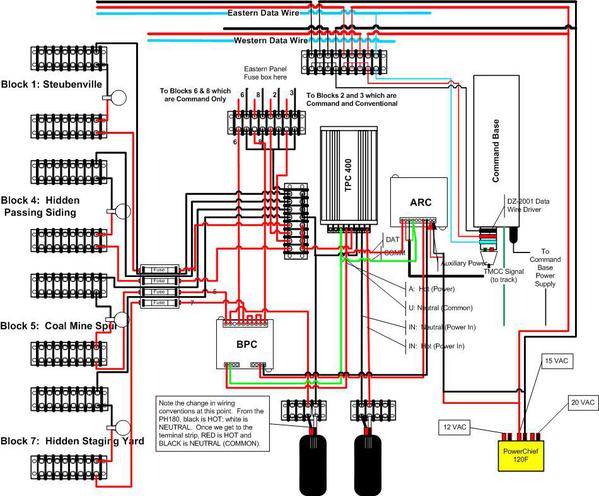

Electrical Goals

Building the PRR Panhandle was also my chance to learn about sound electrical and command control concepts. The Panhandle was originally conceived (back in 1997) as a conventional layout. I then decided to install TMCC, but was influenced by the arrival of DCS. After trying a DCS/TMCC combination during construction, I decided TMCC was the direction to pursue. In 2007, the change was made to solely TMCC. Home run wiring and light bulbs (as block power indicators) were retained in the design. The electrical plan divides the layout into 8 blocks or power districts – 4 mainline and 4 yards - with the ability to individually control power to the yards. The mainline (districts 1-4) may be run in either command or conventional mode. Yards (districts 5-8) are all command controlled.

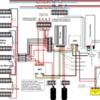

Track power is distributed from two panels (East and West). A wiring plan for the western panel (Blocks 1, 4, 5, 7) is shown below. The eastern panel is comprised of fuses, power indication lights, and terminal strips for Blocks 2, 3, 6, and 8. Track power is provided by 2 Lionel 180 watt PowerHouse transformers.

Switch machines and AC accessories are powered, respectively, by two K-Line PowerChief 120F transformers. Switch machines (DZ-2500a, DZ-2500c) are controlled by push-buttons in the fascia or by CAB-1 via 2 DZ-2001 Data Wire Driver buses. There are 21 switches.

Power for lighting, traffic signals, and other accessories comes from either a 12 VDC regulated transformer or a 3 VDC power supply. Their is a 12 VDC accessory bus and a 3 VDC accessory bus.

All transformers sit on a converted TV stand next to the Western panel.

Updates to the Layout

Updates to the layout (photos, notes, progress, etc.) will always be highlighted as new Comments. Updates tend to appear as a running narrative or blog on the progress (or lack thereof) being made. Your comments and “likes” are always welcome!

100,000 Views and Counting!

I thank you for your viewership. This edition marks the layout’s 5th appearance on the OGR Photo Album since 2004. Over the years, the Panhandle has been viewed more than 100,000 times.

Please send me or post your thoughts, questions, and suggestions in the Comments section.

I hope you enjoy the layout and my journey through its construction.

George