Bucky, thanks for the very detailed trouble shooting guide.  In a "if two sentences doesn't do it, move on, world", it was great to see someone spend the time to systematically trouble shoot a problem. Again, Thank you, Mike CT

In a "if two sentences doesn't do it, move on, world", it was great to see someone spend the time to systematically trouble shoot a problem. Again, Thank you, Mike CT

I've installed several of these 1008 relays on the Fort Pitt Highrailer layout. It appears they, small in size, tend to go bad quickly. IMO the Atlas 6924 relay boards, which are a good bit more complex, than any of the DZ1000/DZ1008 wiring, time out, which limits the number of times the relay functions. Someone told me that the 1008 relays also times out, or they are latching relays, but I could be wrong.

Another problem, that I also experienced with both the Atlas and Ross power routing, is that, all those wheels rolling through a relatively close tolerance track set-up on any switch will eventually cause a short, no matter the switch or the wheel sets. Eventually, after I returned a couple of fried 6924 relay boards, I added (3 amp fuses) to the power routing circuits. Atlas added the (3 amp fuse) to their on-line diagram for Power routing. I also added (3 amp fuses) to the Ross/DZ power routing circuits, Fort Pitt High Rail layout. Sure enough, fuses have to be replace periodically. These shorts at track amperage, IMO, can easily fry such a small relay as the DZ 1008, if they fried an Atlas 6924 relay board rated at 8 amps. IMO.

Power routing was added to both these switches. Note the pens. The distance between these two switch centers, (dead spots), matches a couple of my long connected E8's.

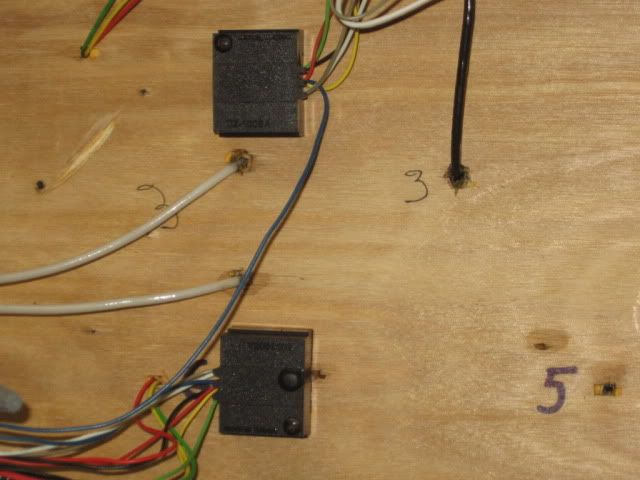

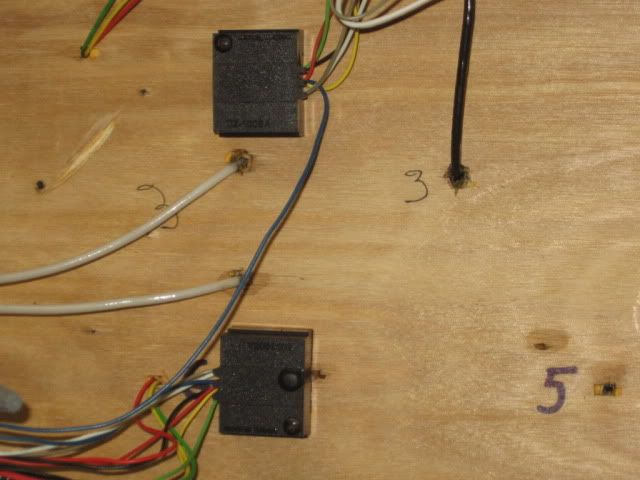

The newer DZ1008, with the leads, can easily be installed under the table.

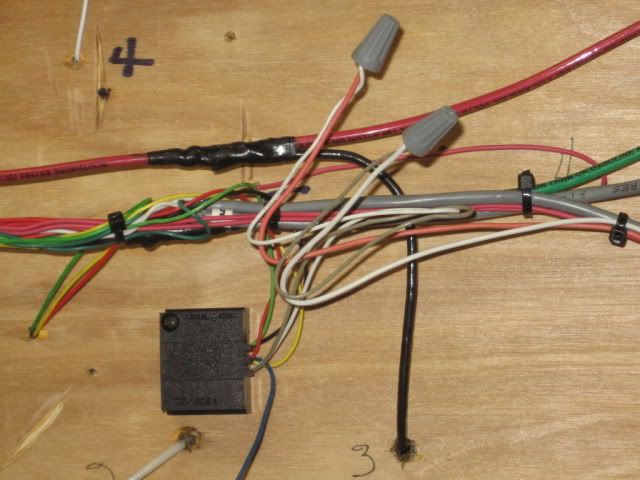

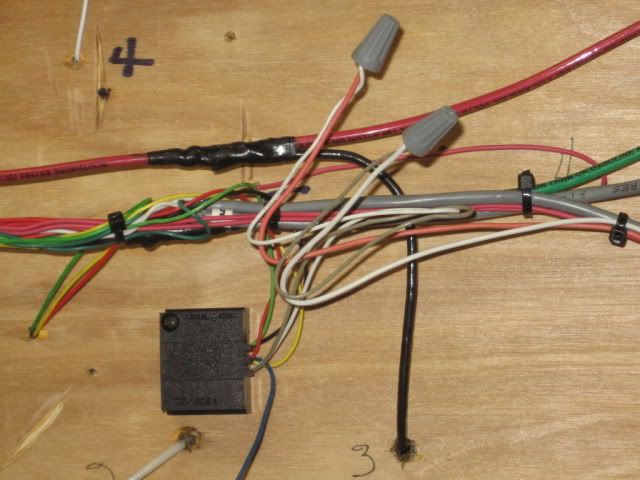

Power routing wires added to the dead rails center of switch. Grey/(or tan) and white wire from the relay. The white from the relay is connected to the red, attached to the rail in this picture. Grey/Tan from the relay is connected to the white, attached to the rail in this picture.

The Fuses were mounted on top of the module, easily accessible, so that they could be replaced. Added ahead of the blue wire on the DZ 1008's pictured above.

IMO same applies to the relays used for power routing on the double slip, IMO.