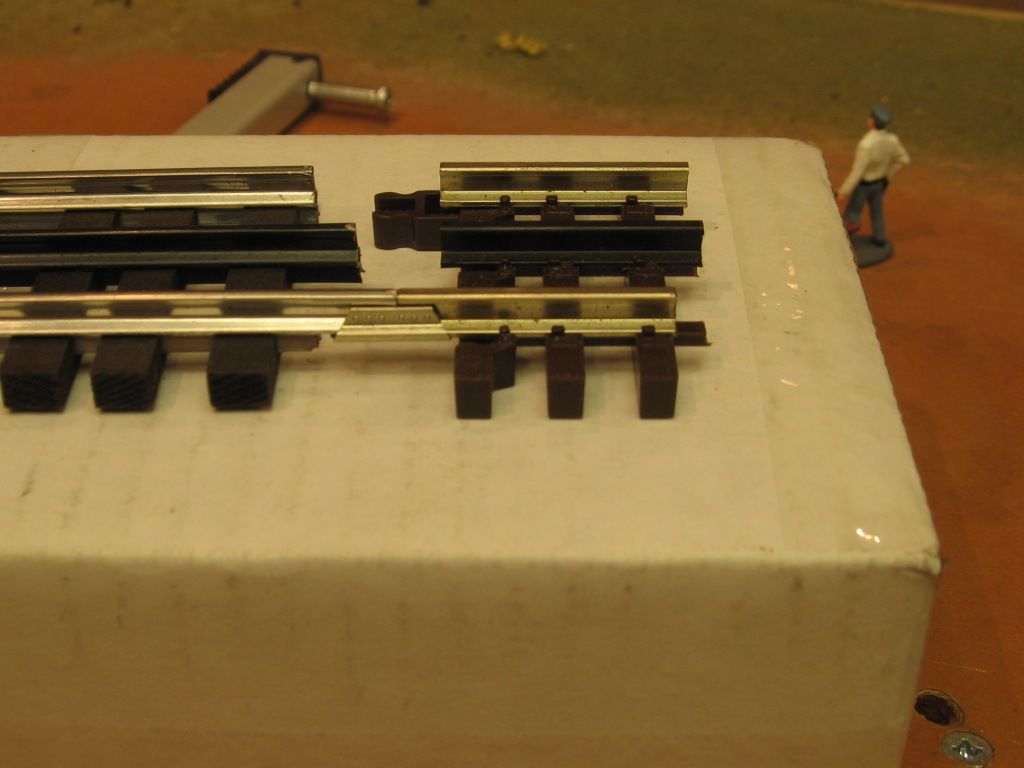

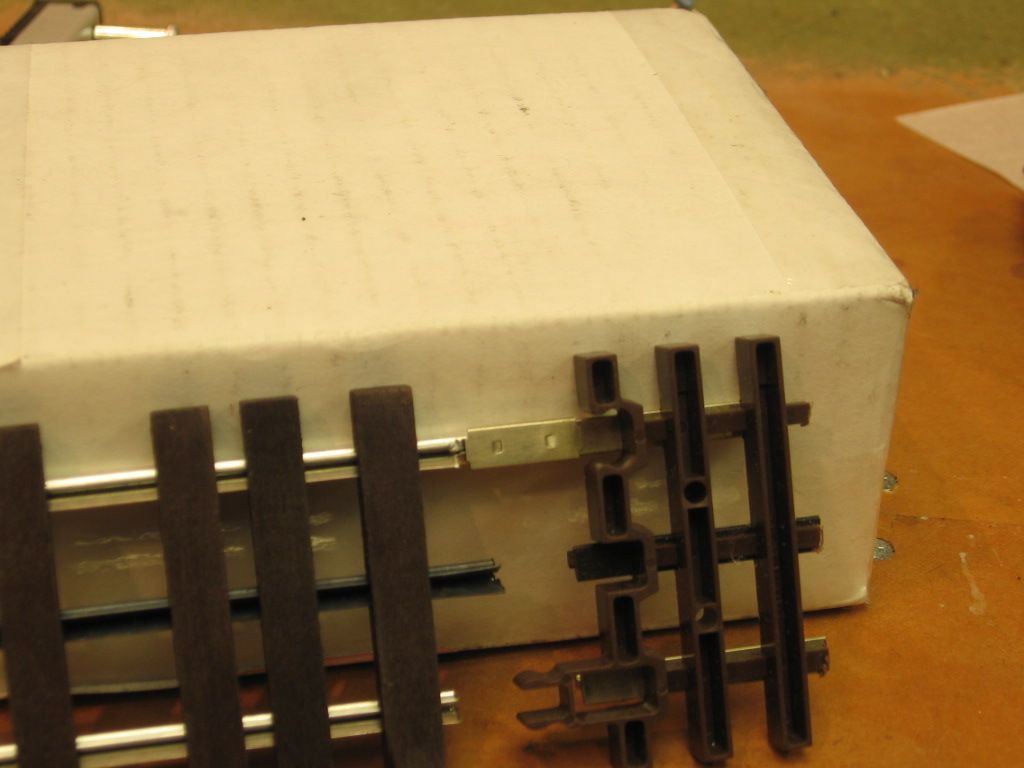

Looking at using Ross track and turnouts on the next construction. However, I dont like the space left between rails caused by the dimple in the pin. I understand why its there, but is there an easy alternative to the standard pin. Such as small bar stock, if so, does anyone have the size that would fit?