Replies sorted oldest to newest

Gene

Soldering fine mesh material always runs the risk of clogging up some of the pores. Back in my HO days I found that 3M spray adhesive worked well for putting on similar F-7 stainless steel side grills.....DaveB

Dave,

FWIW, when Norm asked me about this the other day, I told him I don't like TIX. I prefer Stay Brite. I buy mine from Rio Grande but only because it's convenient to order from them while I'm ordering other supplies.

I prefer the way it flows and seems to be stronger. I know there are some that prefer TIX though.

I think the real trick is making sure any clear coat is removed from your model and use the solder extremely sparingly.

I also like to use Plum-Aloy solder paint. It requires a little more hear though and you'll have to be careful not to warp the thin material, used to create the running boards.

All need good clean up after soldering. I use water and a soft toothbrush. A little baking soda wouldn't be a bad idea either.

My 1 1/2 cents,

Jay

I used Lenox SS flux

the right temperature and 60/40 (no rosin core)soldering is fine.

apply little amount of soldering at the time.

wash after that.

https://www.pricefalls.com/pro...zz38YCFQqIaQodalYHoA

Gene

Wow!! I'd be searching even further, folks!!

First, let's be sure were talking the same animal. Our (LHS) Sta-Brite silver solder is 3/64" dia., 1/2 oz. quantity, flux bottle included. Our price is less than $10...and that's not a sale price!

Our principal distributor source is Great Planes Model Distributors, a major supplier to most retail, full-line hobby shops. Ergo, if you have such a LHS in your area.....check with them!!

Interesting that this thread re Protocraft roofwalks came up... Just yesterday I was searching the web for an alternative source to Precision Scale for 40' walks. I have several packs of PSC's 40' and 50' walks. Up to now I'd only used the 50' walks on several All-Nation, old Athearn car kits I'm finally building. (Don't care at all for the kits' representations of metal roofwalks!!!![]() )

)

When I opened a pack of PSC #452 40' walks, I found that the side rails of the etching had separated from the grid portion. Apparently the etching was too severe and weakened the connection points along the full length....weird. Short of a major bit of soldering work (![]() ) I'm not sure how to salvage these. Haven't called PSC, yet.....maybe should.....they were purchased a loooonnnnng time ago, though. The 50'-ers didn't/don't have this problem.

) I'm not sure how to salvage these. Haven't called PSC, yet.....maybe should.....they were purchased a loooonnnnng time ago, though. The 50'-ers didn't/don't have this problem.

Anyone else have this experience with the PSC 40' walks???![]()

BTW, besides PSC and Protocraft, are there any other sources of metal roofwalks out there I may have missed???

KD

Dave,

Not to confuse you anymore than we already have, but you may want to try the flux Andre suggested. Sounds like it's meant for stainless.

Using vinegar is a waste of time. Many will tell it it will etch the surface. What we purchase at the store is so diluted it's worthless. I have a bottle of 99% glacial acetic acid (the acid in vinegar) and when I place a piece of brass in the solution, even after an hour, nothing is etched. By the way, vinegar has about 3 to 9% acetic acid.

Using vinegar for etching metal prior to soldering is a myth.

Jay

Thank you!

I soldered all the supports first then the whole piece to the roof.

Thank you, this is a scratch built car using All nation end and Proto craft details parts.

the running board are really nice and give a nice looking.

Before Soldering align the running board pieces using few brass rod inserted on both pieces to avoid any movement between them.

Apply flux with a Q tip on the edges Place you have to apply the solder) and solder using a little amount of solder. Too much heat tend to deform the pieces, so solder one point at the time.

Why I don't like silver soldering just because the melting point after soldering is higher and somehow is more breakable. IMO

AG.

Dave,

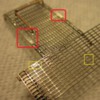

Is the picture or you just used one one piece?

the running board const of two pieces (6 total) that have to be soldered together.

anyway look you did a nice clean job there.!

Andre.

The Protocraft parts are already as thick as any AtlasO, Lionel, or Plano running boards I have, so I did not double the thickness as intended by Norm.

Installing both running board make a total thickness of 0.033" that is in 1:1 is 1.5". Still not really noticeable.

Andre.

This is an interesting topic. I learnt a lot about soldering but could someone advise any book that would be a good reference for soldering? I have a cheap electric soldering tool that I bought years ago at RadioShack that I use rarely to solder wires to track connections. But after reading this thread I am beginning to imagine the vast types of projects I could undertake if I had the proper tools, skills & a reference book. I could make catenary poles & associated structures like the prototypes I grew up around in India. If there aren’t any good books on soldering, are there any website that has guidelines based on the brass type (sheet or rod), composition & thickness would recommend the wattage / temperature for the tool, the recommended solder wire composition / thickness, flux composition (integral to the solder wire or separate pen / solution)?

Thanks,

Naveen