I have Gargrave 115 and 116 042 SS switches. I am using Gargrave Phantom SS track. I am having lots of sparking with both locomotives and cars. Any ideas where to start in analyzing the issue? I assume a spark indicates a "short". I have common "ground" running through both outside tracks. All transformers are in phase.

Replies sorted oldest to newest

Sparking at switches often is a wheel flange making contact with a powered rail in the switch. Look for a burn mark on the rail and you can put a piece of tape there.

.....

Dennis

With some Gargraves switches you lose the outside rail power especially the 042 switches. Have you made sure that you have both sides of the outside rail being supplied power?

One of my problems with Gargraves switches is when I put them back to back without any piece of track between the two switches. If you use 2 Gargraves switches in an S configuration then you must add a short piece of straight track between the two switches, usually a one to two inch piece will work and supply both outside rails with power, as the set-up will cause outside rail power to be lost.

On some of the older Gargraves 072 switches you must supply center rail power on each center rail coming off the switch both straight & curved. Some of the older Gargraves switches don't have a wire inside that will supply power to the other side of the center rail.

Lee Fritz

The majority are 42 and some are recent, last yr or two, and some are 10 yrs old but new. I have checked power thru the outside rails and they seem to be solid. I do have 3" pcs of short track between all combo of switches. I have the short pc between switches powered on center rail with same power as center rail everywhere. Could I be losing it inside the switch?

I thought we were talking about sparks, not loss of power?

.....

Dennis

The majority are 42 and some are recent, last yr or two, and some are 10 yrs old but new. I have checked power thru the outside rails and they seem to be solid. I do have 3" pcs of short track between all combo of switches. I have the short pc between switches powered on center rail with same power as center rail everywhere. Could I be losing it inside the switch?

Have you powered up the outside rails between the switches? That is a common area for Gargraves switches to lose power and most people don't think of.

That is why I suggested adding power connections to the outside rails of the Gargraves track between switches.

For any circuit to work properly you must have both the negative and positive wires connected at all times.

Lee Fritz

Still have some Weaver cars that don't get along with my switches. The gauge of the wheels on the axles are off. I painted the inside of the power rail where it faces the outside rail with liquid electrical tape. No more sparking.

What Dennis said, wheel flanges. Look for arc marks.

get down in there like an O Scale track inspector and determine the location of the sparking. That is both the location on the switch and the location on the truck.

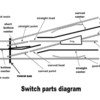

That will help determine the cause and find a solution. Switch anatomy attached from RCS. Observe the areas where the center rails are closest to the outside rail and a wheel could be close enough to cause a connection(spark).

The transformers may not be phased if you are using a surge protected type power strip. if you are, try just a multi-outlet device and see if the sparking stops.

Attachments

We have some Atlas switches on the club layout that certain locomotives will short out going across. As others have said, looking for the arc marks is how you find where the problem is. It may be a good idea to clean up the switch so there's no marking, then work on getting a "fresh" set of marks.

I have Gargrave 115 and 116 042 SS switches. I am using Gargrave Phantom SS track. I am having lots of sparking with both locomotives and cars. Any ideas where to start in analyzing the issue? I assume a spark indicates a "short". I have common "ground" running through both outside tracks. All transformers are in phase.

Are you going from one track power source to another? Do you use block sections powered by different transformer handles or terminals?

If your voltage is not matched correctly when going from one power block to another you will get sparks no matter what else you try.

I am not a big fan of phasing transformers, would rather use a post war ZW with four power outputs on one layout then put two or three transformers in phase.

To check that you are in phase with your transformers; put a light bulb between the two commons(one common from each transformer to the light bulb) and see if it lights up, if it lights up you are not correct or have other problems.

Lee Fritz

All of the power to the switch is coming from one transformer so the issue of phasing doesn't apply. See the pic of a Gargrave 42 switch I have colored in the power measured from my actual switches. Sparking is an issue, so is the locomotive losing power. I know different engines have different pickup designs and I wonder if that is an issue. But why do normal box cars spark as they go through the switch? Is that what was discussed, requiring a piece of electrical tape to keep the wheels from touching both Hot and Grn at the same time? I have not been able to see any "burn" spots...does stainless track burn as easily as others?

Attachments

The tracks on all ends of the switches are all powered directly from the transformer with common on both outside rails.

Check the clearances of the throw bar and the bottom of the rails circled in blue.

Check the clearance of the tab that mounts the points to the throw bar to the center rail.

Also, try backing out on the screws, if any, used to secure the switch to the table. Too tight can cause flexing and misalignment. Most times, you don't need to screw them down.

Attachments

Stainless burns are harder to produce, and soot is easy to be wiped, or even blown off. Look close for pits, "marbles", and/or carbon.

Ive had the crushed flat spot on some axles wear down, and the associated wheel thrust areas cup in, till the wheels could slide inward on the axle, narrowing the wheels gauge enough that in the turn, it hit the big center rail between the swing rails with a wheels back side. Lionel turnout, but the same issue could apply. If track gauge of the turnout is off too! The inner or outer rails may also just be drawing from one side to the other through the box car wheels-vs- an intermediate or weak connection. I'm also assuming there is no anti derailing circuit to help thicken the plot on what's creating the sparks. Good feeds near all outer rail sections? I like to wire a jumper to each outer rail at my power feeds. I like to use feeds near each turnout leg too. I still haven't met a turnout that liked every train I own![]() . The tape might have to be moved for different locos too

. The tape might have to be moved for different locos too![]() . But normally stays put, and lasts longer than you might expect

. But normally stays put, and lasts longer than you might expect![]() . Remembering the "sweet spot" for each loco is another issue

. Remembering the "sweet spot" for each loco is another issue ![]() .

.

I have both Gargraves and Ross switches on my layout. A couple of my Gargraves switches will spark for certain rolling stock but the same rolling stock through Ross switches no problem.

Adriatic just touched on the possible problem. So, let's clear that up.

How do you operate the trains, conventional or command?

How are your switch machines powered? Separate power or track power?

Based upon your information with the diagram, it sounds as if you have a separate accessory transformer.

Have you wired the track to the switch motor connections for the non-derailing feature?

If you have, there is the possiblility of bridging the track transformer with the accessory transformer using Gargraves instructions for non-derail wiring.

Do have any 2 switch crossovers?

I do have a separate power source for the switch machines. I will loosen some screws and try the various ideas put forth. Thanks for all the help so far. With all these brains and years of experience I know I can resolve this issue. I will look at the clearance on the switch bar and tabs.

Thanks. I let you know.

Look at the wheels of a car that is sparking. If you can see burn marks on it, that might help spot the problem area.

It took a while but I finally was able to detect the arcing at the switches by paying close attention to the rails. The stainless don't show the burn marks as wll but they are there. I have used some input from Michael at Gargraves and I have applied coats of finger nail polish to the sides of the offending rails. Care was taken to remove any excess from the top side so power could flow properly. I don't know how long the coating will last but we will see. The older Lionel trucks have a lot of wheel play and the wheels will ride over and contact the middle rails of the switch. The GREEN color is the edges painted with finger nail polish(bright red) so I can monitor wear. I'll keep you posted.

Attachments

I had a sparking issue with two Gargraves switches. Upon close examination, I found that the center power pickup pieces were just a hair too close to the closure (?) rail. When a wheelset ran through that was too narrow on the back-to-back wheel dimension, the center pickup would short through to the outside rail causing the sparking. I carefully bent in the side of the power pickup very slightly. It was enough to give the clearance needed. The area is exactly where the red lines are on your illustration. Maybe moving those two rails a smidgen closer together will give you the clearance you need.

The problem also pointed out that I need to pay better attention to wheel gauges!

Neil

I considered doing the same but I will see if the nail polish insulation hold up for a while. So far no sparks. When you look at the newer model of the switch you see that the center power rails are now one piece and are somewhat narrower than the older rails.

Thanks.