Fantastic! Really starting to come together! ![]()

Many thanks, Mike!

Moment of truth will come when I will put together the faces and fit them on the chassis....It's the moment where I will see if I have made mistakes or no!!!!![]()

jpv

that's great progress. you'll have much satisfaction completing this car.

well done!

Thanks Chris; I was looking forward to reach this step!

But some more work is waiting for me on this project......![]()

jpv69

Wow, each new photo is amazing. Such a shame that a lot of your work won't be able to be seen, probably not even though windows. But there's a satisfaction in knowing you did everything, whether someone can see it or not.

Once this car is done and running on a layout, I'd love to see video as well as photos of it.

I hope you intend on doing a magazine article on the build of this car!

Oh JPV good work!

Ive said it before; thank you very much for sharing your enthusiasm and skill.

JPV69 Amazing!!!! What a beautiful build. Truly fantastic workmanship with exceptional eye for detail. All i can say is that the only thing I can find wrong with the car is that it's not on my layout.

Thank you fellows for your kind comments! ![]()

Lee----> For me, write a magazine article would be very hard and very loooong because I don't have a full knowledge of your language; I don't speak fluently and I have always the dictionary beside me!!! if I would write, this would be for the second one because the way to build it will change and will be more fonctional and logical; this one is a prototype on which I look for better ideas and design. But I will speak about this new design soon in this thread.

Eric----> Pleasure to share; that's why I subscribed to this forum! here, the O scale is a very closed place and if you build US models or an US layout, not many people find an interest to follow you! that's also why I don't post on the french O scale forum anymore: it's a shame but to read some unpleasant and sarcastic comments make me angry and in this case, I answer nastily (french language is very rich in words!) ![]() !

!

Scale C D----> I have the car but no layout; you have the layout but no the car! what to do? ![]()

Bonjour de France

jpv (frozen!)

JPV69 I have the answer ship car this way(just kidding) have you looked at our website at what products we offer.

Well, send me your layout! ![]()

Your web site is in my favorites box for several monthes! very interesting indeed for some pieces I will need later! ![]()

jpv

Received yesterday the first parts for the trucks:

Unfortunately, the 4 pieces in the middle ("longeron" in french, chassis side piece perhaps for you?) are too large (7,2 mm on average) instead of 6,9 mm and have some miner defaults due to the fineness of the drawing. The bolsters (top left and right are very well done.

Here are the axle boxes with the hole for the brass bearing (ruler in mm!)

So, the chassis side pieces will be re-done soon; as they are today, I can't make the assembly because the bolster don't fit exactly with when I put the reinforcement part (bottom left and right on the photo) which has the exact size; you can see the complete truck 3D drawing in a previous post. Sorry, not easy to explain...! ![]()

jpv in France

Attachments

I spent the last ten minutes looking at the progress of this car - it looks so cool! It probably cost a fortune to pay for the 3D printing, not to mention the failed parts you threw out. I would never have the patience to do this, seeing it took you over five months and counting.

I'd love to use a 3D printer to make parts to convert an O Scale SD70ACe into an SD70ACS.

Excellent work! I have experimented using the Micro-Mark metal foil on the slab sides of printed plastic parts. This provides a prototype stainless steel look. The sheets have an adhesive and are burnished to the printed plastic.

It makes sense to me, JP.

I admire your patience. ![]()

Thanks to you all, fellows! I know, I work on this car very slowly.....but I'm dependent on my friend for the 3D parts and he don't work only for me!! more, it's the first car I make, so I have to be careful during the development phase. So, patience is the master word! if I reach my goal, the second one will be easier to build! 3 essential steps (in french!): prototype, pré-série, série! never to place one before another! that's what I learned when I was working in the french railways society (SNCF)! and the prototype phase is always the longest.

In fact, I'm having a lot of fun to work on this plan!

See you soon

jpv in France

Hello all,

New and re-done parts arrived yesterday evening!

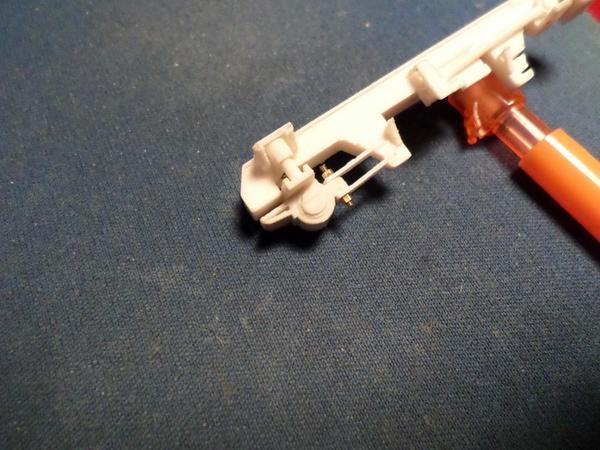

So I began today the building of the first truck:

first, assembly of the main damper (upper part) on the bolster with brass bolts and nuts 1 mm:

Then fitting of the sides on the bolster with polyamide bolts and nuts 2 mm

Insert of the bearings inside the axle boxes:

Now, I'm waiting for the springs (the truck will be suspended), other (very ) little bolts and some brass pieces to keep on working.....

jpv in France

Attachments

Beautiful work ,

I was looking at your axle bearings , they appear to be bored off center . Not criticizing but alerting you as I have had bearings made and they were bored off center , had to send them back , or maybe it is camera .

Bernie

Thanks, Bernie,

No, the bearings are well centered; certainly the camera and the adjustment I used for macro photo.

jpv69

Just found this topic. Impressive!!! I'm looking forward to watching this project progress!

Hello all,

Too much work in my appartment these last days, so no work on the passenger car!

Now, I can start again!

In the last post, I wrote that the brass strips were too strong; I changed my way of assembly using simply styrene strips of the same thickness.

Here is the first axle box fitted on the truck frame:

The spring is just behind the shock absorber:

And it works!!!!

The nuts are not yet locked; this allows me to adjust the axle box during the final assembly of the truck and wheels.

I can tell you: it's not easy! but "qui va piano va sano!"....![]()

See you soon

jpv in France

Attachments

Love what you have accomplished. Are those plastic trucks going to be strong enough to actually pull the car on rails?

Nice, JP. I must be going a very long way - so slowly am I going at the moment. ![]()

Thanks Ron; these pieces are 3D printed except the 2 styrene strips but they are very short (10 mm); once extruded out of the printer, the material is very strong (ABS).

Thanks too Max! slowly but surely!

That's all for this evening; next ones tomorrow!!

jp

First step for the two trucks done!

Now I'm waiting for bolts ( 5 and 8 mm long) and some nuts I ordered for the second step; they will probably arrive tomorrow...with the new bolster!

Until now, I had 10 mm bolts that I cut to lenght and filed but it's not the best!

Her is also the prototype for the large windows; just some little work with a sweet file to fit inside the faces and it's done!

jpv in France

Attachments

It's beautiful, JP.

Many thanks, Max! ![]()

jp

Fitting of the truck parts: bolster, axles and side frames; all seems to be good; the wheels turn smoothly.

And now, second step: first level of the suspension; funny to put together! irritation not allowed!! ![]()

After attempt, I will have to insert a 2 mm sheet of styrene between the floor and the truck pivot to heighten the car, otherwise the trucks can't move around or a very few; result: I will have to pull down the couplers of the same high!

jpv in France

Attachments

Look good, JP.

How strong is that stuff?

Thanks Max!

All parts are made in 3D printing material (ABS); the parts for the truck chassis (bolster and sides frame) are enough thick to have a very good resistance and they will support the weight of the car without any problem; the little pieces on the second shot have no effort to do; they just complete the truck design. At the beginning they were planned to have a mechanical role but it was to hard to make for me!

jp

Very elegant, JP.

JP, Very nice! Let's get this car hauling passengers! ![]()

wow, I am thoroughly impressed. great work.

I also like your trackwork.

Dan Weinhold

Many thanks to you! it's very kind!

Mike----> I have seen on EBAY some passengers sets (coming from China..!) but I don't trust this website! I have to ask a friend of mine who has an Ebay account to buy them for me!

Dan----> the track and turnouts come from ROCO (bought 30 years ago....); the turnouts are 2 meters radius; never seen so large until I knew the ATLAS 7,5° ones. The ballast comes from a french brand (GPP) which don't exist anymore and it's a shame; it was made from crushed stones (I have seen their amazing factory).

See you soon

jpv in France