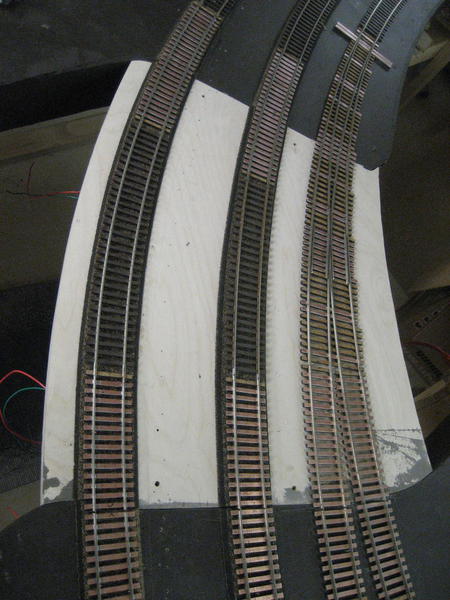

Folks I've been designing a layout and right now the favored design is a double-oval ring of modules with an open center.

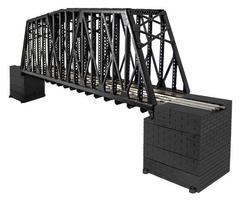

To minimize the amount of ducking I would possibly like to incorporate a lift bridge. It appears that Lionel has built at least two of these: The 12782 and the 14167, aka #213. I also know there was a fellow in the Orange (Toyota) Hall at York, toward the corner near the Lionel display, who builds bridges like this on a custom basis. I think I remember that he's from somewhere in the deep South. I got his business card in October and somehow managed to misplace it.

My concern is that I want the opening to be wide enough that an average person can pass through easily (perhaps 24" wide), and the bridge in the raised position will be high enough to limit the amount of bending required. I'm planning benchwork that gives me 42" to the railhead, so I hope the bridge will get me another foot or so. Obviously a drawbridge or bascule bridge would open at right angles, which wouldn't require ducking at all. If I put a reversing loop across the oval, I may use a bascule bridge to gain access to the center of the ring, and a lift bridge on the diagonal track forming the reverse loop.

So who here on the Forum has the Lionel bridges, what are the pros and cons of each? Did anyone have a custom bridge made, and were you satisfied with it?

Not to take this thread completely off-topic, but I believe Mianne and some other prefab benchwork vendors are now selling a lift-gate which can be incorporated into a layout built with their modular benchwork. This is another option I'm considering, especially for getting into the "ring".

Thanks for sharing your thoughts & experience! -Ted