Anyone who doesn't have to walk, or kneel, on their layout has a pretty unusual situation. In my case, I have hanging art, train display shelves, ceiling fans, light fixtures, a skylight, and a window that cannot be reached without putting my weight on the layout. To configure the room so I didn't need to stand on the layout would have meant reducing the space for trains and accessories by at least 1/3. Everybody's space is different and everybody's needs are different.

I have to make this very decision very soon. This thread is a great read.

another thing i have been able to do is collect many many old pallets and tear them apart and salvage wood, all salvaged wood cut to true 1"X2" in various lengths all of them over 36" and a wide variety of wood, some of it oak, some maple, some??? but nice wood and i actually have a lumber processor nearby and he offered to kiln it for whatever time it needs, just put it on a pallet and let it sit inhis lumber kiln

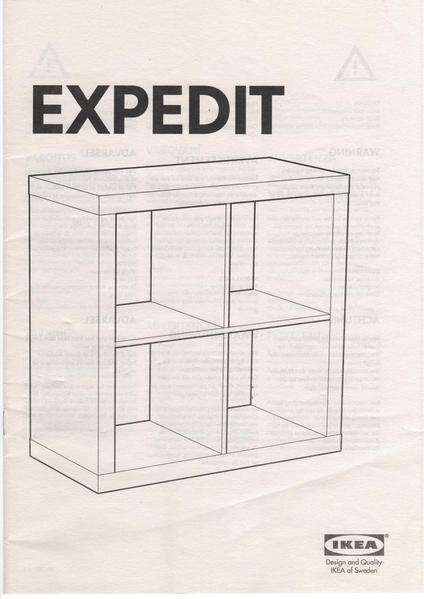

I use 'Expedit' shelf units from IKEA for the 'legs' of my layout.(See image below.) They are very strong, easy to assemble and provide plenty of storage space under the layout. I then just place the framed baseboards on top. ![]() My baseboards are made from a framework of 2" x 1" supporting a deck of ⅜" MDF topped with ¼" sound insulating panels. I can use this lightweight framing, as the Expedit units provide all of the major structural support.

My baseboards are made from a framework of 2" x 1" supporting a deck of ⅜" MDF topped with ¼" sound insulating panels. I can use this lightweight framing, as the Expedit units provide all of the major structural support. ![]()

Attachments

That's actually the Kallax shelving unit by ikea...here in the US anyway. $34.99

30 3/8 inches tall...square...

Hi Chuck. That's correct. I've just looked and it is Kallax in North America, and Expedit in Europe. After having built 10 of them for my layout supports, I can put one together in about 5 minutes now. ![]()

My bench work is made from 1 x 4 pine frame (12" on center) and a 1/2" 5 ply plywood top w 3" legs made from the pieces of 1" x 3" pine with a bolt adjustment on the bottom. The basement is somewhat damp but no problems after 8 years.

I built my layout about 14 years ago, in several sections. It is built with 1x2's and 1/4 Launan wood. On top of the plywood are 2 layers of 2" blue foam, then I added roadbed cut from 1/4 launan plywood. This layout was moved from New Jersey to North Carolina 11 years ago. Since then it has rebuilt from an On30 layout to an 3rail layout. I have had no problems with this type frame work. Charlie

Dennis brings up a very good point. Be sure to get multi-ply plywood. 3-ply, 1/2" plywood is lousy stuff. The more plies, the stronger and more stable it is.

The timing of this thread is great, as it's going over some questions I had as well.

SIRT, what an interesting way to do a home layout. It never occurred to me to make a modular layout for home allowing you to swap parts out to change up operations. I just may have to take that into consideration, but space is tight, and I don't have a place to store unused modules.

But like Hot Water and Southwest Hiawatha point out, by going small and light, you can't get as much trains out at once, and it's hard to work on the walls. I'm sure my layout will be built before the room is decorated, and the only way to get to the walls will be via the top of the layout, thus the need to stand on it.

2x4s are cheaper than 1x4s last I checked, so I'll use the 2x4s. As for 1/2 vs 3/4, I live in a very dry climate, and if I have a tighter cross member spacing, do I need thicker than 1/2 or even 3/8 if putting Homosote on top?

Plywood comes in grades, what I use is: ACX - grade A sanded topside, grade C bottom, and X stands for water proof glue. The more layers the stronger. My layout is built with 1 x 4 cross members on 16" centers and 1/2" ACX plywood. My 6' 2" very overweight bod can easily walk on it. Not a creak or groan. Cabinet grade would even be better, just more expensive. Even if it comes with a little warp, when you screw it down to a frame it goes flat.

Dan

If I understand the construction method here, there is a frame made from 1x2s laid flat. Then there is another frame made from 1x2s laid on edge. The outer dimensions of both are the same. These two frames are mated together (forming a sturdy "L")and turned upside down. The top is then routed to inlay the 1/2" base.

If I'm correct, I find the method quite interesting, kind of like a 2" deep cabinet. It seems a little time-consuming, but I'll bet the modules are quite strong while being fairly light-weight. The layout looks like it could be taken apart quite easily and reassembled just about anywhere there is room, like on top of portable tables, several sawhorses, cabinets like the Ikea mentioned earlier, etc.

I'm really looking for a modular approach. I just found out I may not get access to a spare bedroom now until June 2015 and I'm tired of waiting to run a train. So, I may put together some modules that I can assemble in the garage, on the patio, in the dining room or even straddle 2 sofas we have temporarily set at a 90 degree angle in the (unused for the most part) living room. If I use O31 curves for a loop2loop, I can let the sofa arms support the back and some adjustable legs take care of the front. Once I get my bedroom, I can use these modules for my 3nd level above something with O54 curves. I just saw some L-shaped designs in another thread that I think would fit this idea pretty well.

My layout is all 1 x 4 framing with 2 x 2 legs, 1 x 2 braces and 1/2" plywood (4 ply). Don't use the plywood that is 15/32 passed off as 1/2" and is only 3 ply.

Jim Barrett's recent article in OGR, last month I believe, shows him using the above.

.....

Dennis

1/2" cabinet grade plywood, 2 X 2 legs and 1 X 4 framing and I can stand on it and have. Solid as the Rock of Gibraltar in my opinion.

Art

Legs 2x4s, 1x4s in grid and 5-ply 1/2" plywood topped with 1/2" foam and 5/16" cork roadbed under Gargraves Flextrack.

I have Mianne benchwork, and I have 1/2 inch plywood on it. My layout is on the second floor of a detached garage which has heating and air conditioning.

I'm about 200 lbs. and I have spent a lot of time on top of the layout with no problems.

I have Mianne benchwork, and I have 1/2 inch plywood on it. My layout is on the second floor of a detached garage which has heating and air conditioning.

I'm about 200 lbs. and I have spent a lot of time on top of the layout with no problems.

Ditto. Mianne with 1/2 plywood. My layout has an elevated section and I climb right up to paint, etc. Sturdy as a rock.

I built my layout "My Lazy L" 5 x 9 x 11 on Wheels. I used 9 sets of 3 wheel rollers from Harbor freight. $3.00 each. My layout is 1x4 framework and 1/2 plywood covered with 1/2 Homosote. I can roll it with No Effort.

Works for me!!

I have a round the room modular layout,mounted on L brackets lag bolted to walls at 32" intervals. The bench work is 1"x2" with 1/4" 3 ply birch plywood and 1/2" homosote. The construction method is similar to what Sirt has done, light weight, no warping after 5 years, don't have heat or ac in building yet.

I think what it really comes down to is if you feel better with 2 X 4's and 3/4" plywood, by all means use it. But in my experience it is not necessary from a strength standpoint.

Art

here is my basic, simple layout that i raised up and down with a boat winch on four pulleys, but not a square inch of space not occupied, dont want to tear it apart just to change one building or one scene so consequently the move to make a new building came into being should have room for a lot of track and lots of new ideas about scenes, guess the only thing now is to decide "around the room" or "table in the middle"

OH Yeah one other thing, and my wife wont admit it but she parks her "baby" under my train board and her baby is a Corvette convertible. I know she secretly fears my "O" gauge layout landing on her car

here is simple up and down layoug 9X4 1/2

here is one of the street scenes on the little board

too bad there is not some way to get it to my grand kids in Arizona but aint gonna happen probably cost a fortune to pack it and ship it

I think what it really comes down to is if you feel better with 2 X 4's and 3/4" plywood, by all means use it. But in my experience it is not necessary from a strength standpoint.

Art

Good point. Concerning 2X4's, I found that glueing 1"X4", 40" long pieces on their sides, to make "L" shaped legs are actually stronger than 2X4's. I also glued 1X2's on one edge of 1X4's for the "L Girder" cross supports for the layout.

I think what it really comes down to is if you feel better with 2 X 4's and 3/4" plywood, by all means use it. But in my experience it is not necessary from a strength standpoint.

Art

Good point. Concerning 2X4's, I found that glueing 1"X4", 40" long pieces on their sides, to make "L" shaped legs are actually stronger than 2X4's. I also glued 1X2's on one edge of 1X4's for the "L Girder" cross supports for the layout.

correct, a 1X2 all by itself is not much. However a properly engineered brace out of with one of the correct joints, many to chose from. could me quite strong, If i do it right i can enclose much f what is seen under the layout. Lots of lockers for "stuff"