I’m building a portable O27 Lionel layout 38inches wide by four feet long. I’m using tubular track. My question is what is the best way to keep the noise down. I know toy trains are loud and I wont be running the trains at a fast speed. I have found a tip using window and door sealing foam strips under the ties helps keep some noise down and helps anchor the track to the base of the layout. Also is there options besides using foam board on the base of the layout to keep noise down that won't be expensive?

Replies sorted oldest to newest

I have used foam board, but the quietest track I have seen/ heard had carpet under the track.

If you are going to ballast the track, just put foam track bed under it. Like if you were using atlas or gargraves track. Also, alot of guys swear by homasote board. Its a type of drywall? Another tip is dont drive the screws you attach the track with down into the wooden studs of your benchwork or into the chipboard that may be below your foamboard. I used lionel fastrack for my layout. Installed on top of foam track bed, on top of 2" blue foam board. It was very noisy at first. But when I placed ballast around the track, it quieted down alot!

Attachments

Just run it next to a FasTrack layout, nobody will hear the O-27 layout.

Adding a layer of foam rug padding (the kind placed under wall to wall carpeting) over the entire board should help mitigate noise. Screwing versus nailing the track will also help too.

-John

Just run it next to a FasTrack layout, nobody will hear the O-27 layout.

Or leave the trains off.....

One question about the foam under-carpet padding: Does this stuff begin to crumble over time. I'll be using the Johnson rubber roadbed under my tubular, but there will be some pieces missing, especially under switches and that's where I'll use the carpet

padding. No ballast, just a little paint to match the Johnson's.

Hoppy

Seriously, though, my O-27 Christmas setup is pretty darn quiet on tight cut loop carpeting - all you hear is the trains. See if you can get a remnant that would serve as a good base.

Seriously, though, my O-27 Christmas setup is pretty darn quiet on tight cut loop carpeting - all you hear is the trains. See if you can get a remnant that would serve as a good base.

Very nice setup. One question, what kind of smoke fluid do you use?

Art

Can't remember specifically, could have been Bart's, MegaSteam, MTH, Lionel or Lionel pellets. That engines smokes up just fine with anything. The pellets last longest.

I have a small portable layout that I used Macklanburg-Duncan felt weatherstripping for a roadbed. I used two widths of 3/16" x 1-1/4" side by side for a 2-1/2" roadbed. I stapled it to the table top. Seems to help quite a bit to keep things quiet.

Sound reduction must be balanced with other factors in my opinion. Carpeting is excellent from the many times I've seen it used at portable train show displays. Unfortunately, it is difficult to erect signs, trees, and other landscaping without heavy glue or screws. I am not sure about its flamibility depending on the materials used and whether your train has sparking. Homasote, the ubiquitous material for sound deadening on layouts, is almost like foam, but suffers from the same thing as carpeting for the stable placement of items and fixing down track. Although a smoother surface than carpeting, You can't use screws well and have to use glue to hold things down. The screws won't hold well. My preference is first to increase mass by cutting a piece of drywall to the size of your platform. The platform can be 1/2" to 3/4" plywood or any other wood (like particle board) you want to use (I don't use particle board because of the formaldehyde binder used in its formulation--but it is definitely firmer than plywood). The combination of drywall and wood platform gives you the mass almost like running your train on a cement floor with very little vibration. Keep in mind that vibration is what makes sound. The next thing is to either use a roadbed made from foam or cork for your track or else line the entire platform with cork which is what I did. You can use sheets or cut the cork from rolls in the size to cover your platform. This cuts down on surface vibration and also holds screws much better than foam when fixing down your tracks. By using cork over the entire platform also cuts down surface vibration from operating accessories on your layout. I have also placed blue sill plate foam under switches to further reduce that noise and done the same with some operating accessories, like the Lionel gateman. In screwing in the track ties, I put a dab of non-hardening caulk between the screw heads and ties. The screw itself never penetrates beneath the cork. All the ties have foam strips cut from a roll that is normally used as weatherstripping. I do not use many screws, just enough, especially at curves, to keep the track stable and a couple along the straight runs. Too many screws, if they penetrate into the platform can cause vibration to be transmitted; however with the drywall underneath, probably will not to amount to much noise from that vibration. That is the good thing about increasing mass. Recently, I ballasted my 0 gauge tubular with gravel stones used in fish tanks, with some glue and double-faced tape at the bottom to stabilize the stones. I think this also reduced vibration along the tracks, stabilized the tracks, and made for less noise. Perhaps this was due to another increase in mass along the tracks because the surface noise of the cars going on the track now is not as great and the track seems more solid on its surface with all the stones inside and out along the edges of the track. I incorporated another suggestion which I think is more theoretical than practical: I used pillow fluff inside all my boxcars and covered hoppers to minimize any vibration from the wheels and trucks that could be transmitted to the body of the car and amplified by the hollowness of the car. Again, I did not notice any apparent difference in noise level, but it may be more minor than significant. Finally, make sure you have close bracing of benchwork, especially on large boards without drywall underneath. Insufficient bracing can introduce vibration of the platform creating a drum head effect. I also have my layout on a carpeted floor which helps minimize sound emanating from under the platform that bounces to the floor. Hardwood floors can bounce the sound around creating an echo sometimes. I run eight trains and a trolley on my layout simultaneously, using separate loops; so you can understand why I am somewhat interested in this topic. Originally, before I revamped my layout, no one could even hear each other talk from the noise level.

I have small layouts with tubular rail laid directly on bare door-panels and I don't consider noise to be an issue. I just don't run them all day long, and the train speeds aren't real fast.

I have a larger floor layout laid on carpet with longer and faster trains, and that works well too.

To get away from roadbed/bench top issues for a moment.....

My layout uses Lionel tubular o gauge track. I realized that a lot of noise - clickety-clack from wheels and pick-up rollers - was being generated by gaps in the rail joints. These gaps were the product of curves not working out just right, insulating pins creating gaps in the adjacent rail joint(s) and the occasional failure to pull joints up tightly.

There were also a few "bumps" at the joints caused by pins flaring the mating rail.

Both of these issues were addressed by carefully cleaning with alcohol and then applying JB Weld to the space or flare.When cured, the JB Weld was dressed to rail height.

The sound reduction was remarkable. The quietness is comparable to running on 40" straights, as opposed to four 10" sections.

Also, gaps have very sharp edges. Filling these gaps has greatly improved the life of traction tires, which were being quickly and severely frayed, especially on curves (0-31,0-42) where one tire was slipping due to traveling a lesser/greater distance than its mate.

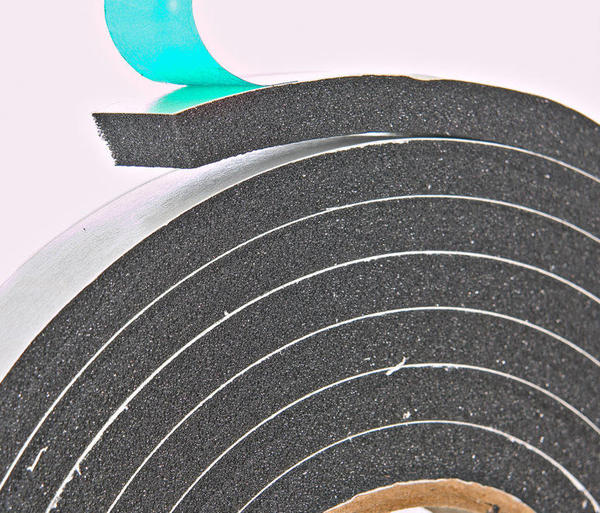

Get something like this. Stick it to the underside of the ties. Make sure it is thick enough to keep the ties well up from the layout top. Use zip ties to hold the track down to prevent vibration being transmitted between the rails and layout board.

Steve

Attachments

I am not sure about its flamibility depending on the materials used and whether your train has sparking...

Carpeting is fireproof. It's an arsonist's nightmare.

There has been a suggestion that carpeting is fireproof; however, I have seen layouts with a type of indoor/outdoor green carpet that seems to be made of a plastic man-made type of material rather than fiber. It is true that carpet can be made safe depending on the chemicals with which it is impregnated, but I am not so sure with that indoor/outdoor carpeting. Of course, the probability of a fire is extremely unlikely, but any heat source that is concentrated could melt that man-made material if left on it for awhile. Again, I am not that familiar with it that much; so it is worth checking out before purchasing any. I have asked a man with such carpeting about it and he said he never had any problems, so I guess it is OK. Regarding using JB Wield for your track junctions, I have yet to be able to join tracks successfully with this technique using solder. I suspect I would have the same problem with JB Wield. Unless the solder or J.B. Wield is flush with the top of the track, there will be a bump at the joint that could cause a derailment with light cars. That is why dressing the joint or smoothing it flush must be done before it dries or you will have to file and sand the joint. For straight track, try longer sections that are one piece rather than the regular size ones to eliminate the joints in the first place. I agree that flared edges and gaps in the joints can wreck havoc with the rubber tires on engines; but if you are running old post-war engines without those tires, there should be no problem. The other disadvantage of using any glue or adhesive between joinders is that you'll be unable to disassemble the track sections for any changes in your layout, at least easily so. Regarding sound levels, keep in mind that sound is transmitted by vibrations. The one way is to keep vibrations from occurring in the first place is through the use of heavy mass materials. The other approach is to use different material densities such as cork, foam, homsote, etc. to dissipate its effect in your layout through absorption of vibration. The best solution is the use of both principles in my opinion. Carpeting is actually good for both in a sense because of its weight and absorbency, but with the disadvantages noted in my earlier post.