Jeffery,

I made some changes based on what I would do, and they may not be what you would do. So take them as recommendations only.

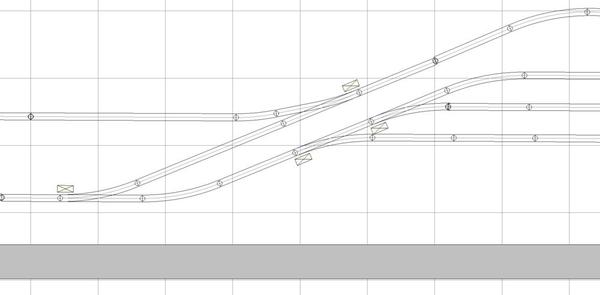

1. In the upper left of your track diagram it looks like you have two tracks that run parallel to each other through 180 degrees of turn. These tracks get farther apart around 90 degrees of turn. I like my parallel tracks to be parallel, so I changed the tracks to remain parallel at 4” center to center. I also changed the curve diameters to O-80/O-88 for better clearance since Ross curves are only on 4" centers. Check the Initial curve pieces, they start larger (O-88/O-96) then get smaller to make the 180 degree fit plus act as transition curves.

2. Added 2nd crossover in upper left for added flexibility. I used #5 switches because this arrangement of the switches does not have an S curve issue.

3. The 4-track yard in the lower right used O-64 switches which I do not believe are good yard switches. I used #4 switches for the yard. You lose a little length, but get a 5th track. Also, the #4s will provide more reliable operation for backing through the switches.

4. In the lower right I used a #5 switch and a section of O-96 curve to smooth this turn out. It will look better with all sizes of rolling stock and be better operationally.

Just some of my thoughts. Have fun finalizing your plan.

![]()