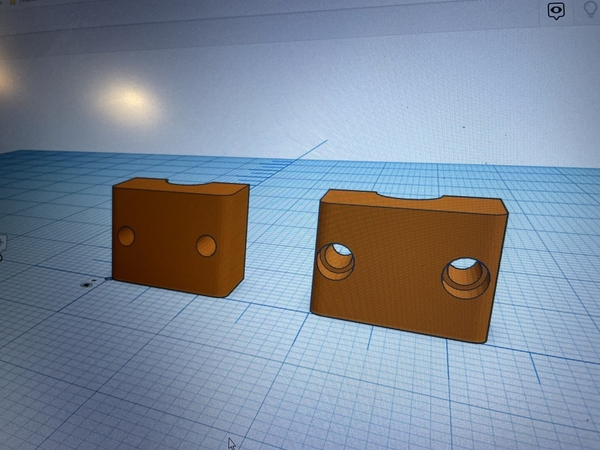

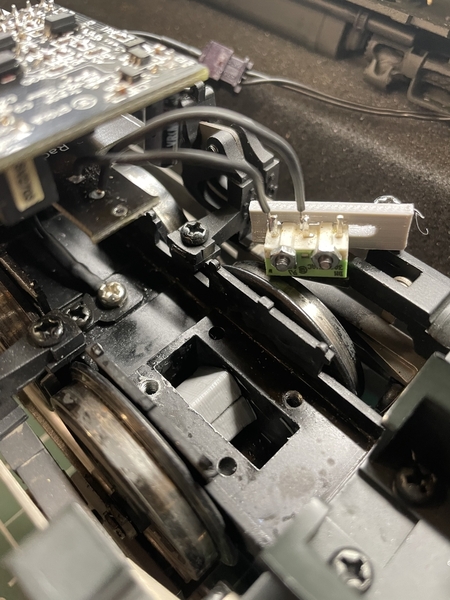

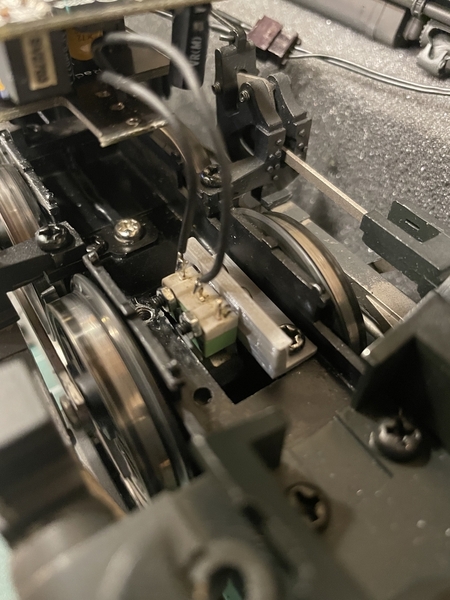

I am having almost too much fun learning about 3D printing. I primarily wanted to make internal parts to help improve my engine and rolling stock projects. My beloved TMCC Lionel J1a always had something close to the proper chuff, with two magnets on one of the trailing truck wheels pulsing a reed switch, giving it 3.8ish unsynched chuffs. Even when it had EOB years ago, the chuffs were pretty proper but definitely unsynched. I thought it might be nice to try making a proper 4 lobe cam, which is just a square with rounded corners. Adjusting the cam rotation could get me synched chuff on the crankpin at 0, 90, 180, and 270 degrees. PSC sells a similar device in cast brass but it is probably more practical for smaller scale models. Turned out I needed a microswitch bracket too as the original is long gone along with the smoke lever for the postwar style puffer unit this had originally. After some trial and error, I got it all working a couple nights ago. I learned quite a bit about dimensioning parts and making slots for component adjustment. The cam halves are CAed together and to the axle. I like that the PLA takes to gluing. I probably made 3 or 4 different switch mounts and two cams. My next cam will probably be mounted with small screws like the original sketch shown below. The width of the cam (9mm here) and the placement of the switch are dependent on how much lateral axle movement there is, but this axle is pretty tame in that axis compared to a lot of 3 rail stuff.

Attachments

Original Post