@bmoran4 posted:The '46 726 is very similar, and Olsen's actually went through and took the ' 46 726 instruction sheet and updated it to be applicable for the '46 671.

I did find spot that and found it to be helpful.

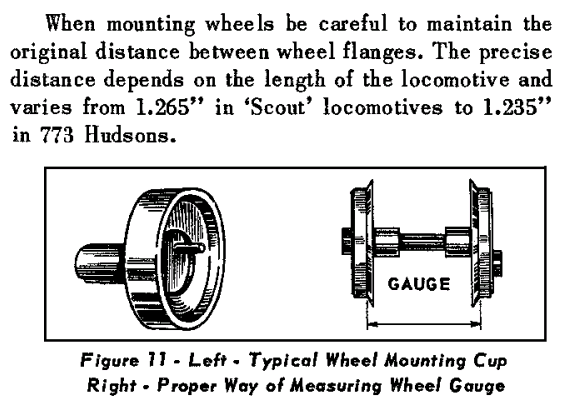

I haven't uncovered anywhere where Lionel lists the explicit wheel gauge out side this generality:

Hope this gets you on the right track.

What gives me pause is that I normally measure from the intersection of the tread with the flange, to the same location on the opposite wheel - just as shown above. With a nickel tire on there (especially a tire with some "wrinkles" to it) you can't measure from that point - no way to get my caliper down in there!

This is a drawing I made quite some time ago,

I forget the exact reason - but it shows my concern with gauging wheels that have (in this case, nickel) tires on them. I believe I will be better off just taking measurements on existing conditions with the wheels I will be removing (perhaps from the backside of the flanges or the outside of the nickel tires), and then shooting for the same measurements upon reassembly.

To top things off, one of the flangeless wheels took a hit at some point in time, and the nickel rim now has a bit of "wiggle" to it - not loose, just a wrinkle so to speak. Knowing that these wheels don't really make a lot of difference in the whole drive train scenario, I can live with it. But since I have to remove that wheel to get the rear wheel off, I may as well take a shot at straightening it.

Thanks for replying!

George