It's much easier to do with two-rail than 3. You need to keep the filler pieces below the center rail. I used 1/8" Masonite strips cut on the scroll saw from templates that I made from scale drawings of the Ross curves. The inner loop was O-88 and outer O-96. They were tapered on the ends so they wouldn't snag any equipment and painted weathered black to simulate Macadam. My problem was not with the crossings themselves. It was that some of my roads were coming down a grade and were higher than the railhead. It took quite a bit of fiddling to remove material near the rails so the pilots of some of the big steamers weren't scalping the roadway. Each time I thought I had it fixed, another engine would clip the higher road and scrap material and/or derail.

Fillers hug the center rail and leave sufficient flange way clearance for the O'gauge wheels.

The finished crossing system

Damage done by the pilots hitting the higher-than-rail roadway.

There was the culprit. The Allegheny's low and scale pilot. My J1-a was worse since it was the front truck that hit and kept derailing.

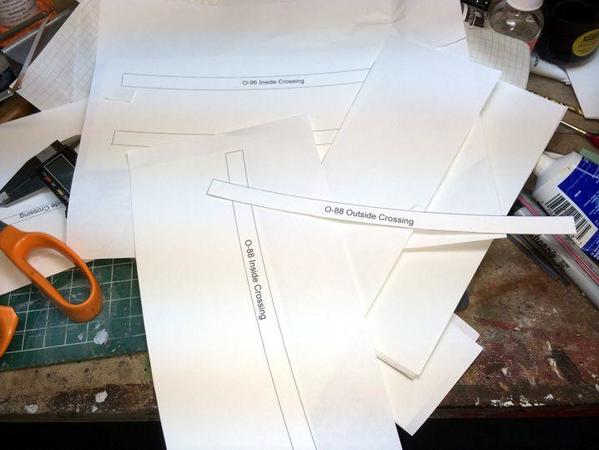

These were the templates used for the different curve sizes. I have those files on my computer if there's any one with O-96 or O-88 that needs them, send my an eMail.