@Mega-Steam posted:......As with all smoke fluids, viscosity (thickness) is another factor that needs to be mentioned. Our standard mid-range viscosity is such that our fluid is safe in all scales and all manufacturer's models. From a chemistry viewpoint, the thicker the viscosity, the slower vaporization and the more droplets will be thrown out on the track and buildings as the flashpoint is higher; the thinner the viscosity, the faster vaporization with occur and the flashpoint or ignition factor goes lower which could possibly ignite. It is important to us and our customers that our viscosity is safe. We will not sacrifice safety.

I have been running a number of my locos which have not had a lot of recent use and was worried about getting the smoke units in shape. In this process, I have been performing due diligence by adding the 40 + (up to 120 per laidoffsick?) drops to get the batting soaked. As many can verify, it can be a PITA to get rid of bubbles, clogs, etc. and get the fluid into the smoke unit batting. In the famous Mike Regan Lionel video (start at about 9 minutes), he calls this issue the film or meniscus effect. In further researching this issue, I looked over this thread and I read this quote above from Mega steam referencing an unappreciated characteristic of smoke fluids- viscosity. This has to also be a big factor on the issues Mike R. notes and related to my recent experience. If the fluid does not get to the reservoir, there is not much debate about which fluid smokes or lasts longer.

As I was running my locos and getting the smoke units primed, I thought I noticed differences in the fluids I used and Mega- steam seemed to reduce this filming or meniscus effect. At the risk of starting another fire storm, I thought a simple experiment was worth documenting for our collective consideration on the erudite topic of smoke fluid. There are a ton of details not covered in my simple test so don't beat me up for those details which I could not measure. Plus, there is another motivation, I have not won the Nobel prize yet so this might make the difference.

The bottom line is I was curious if what I was observing on simply getting fluid into the smoke unit was related to viscosity. Since I have no way to measure that at home, I cooked up a simple experiment to test the ability of the fluid to flow and to penetrate the batting. I had on hand Lionel, MTH, Mega, P&P, and also figured I would try some mineral oil too since it was around the house.

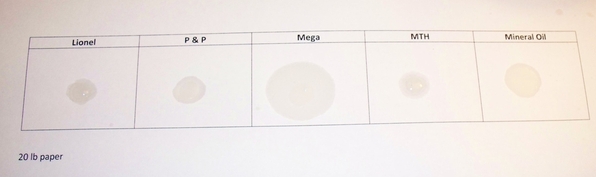

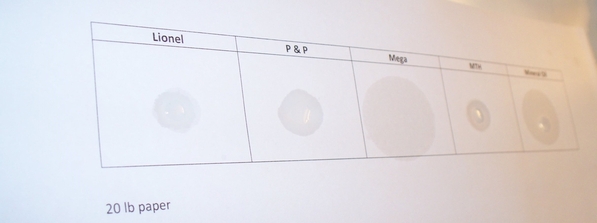

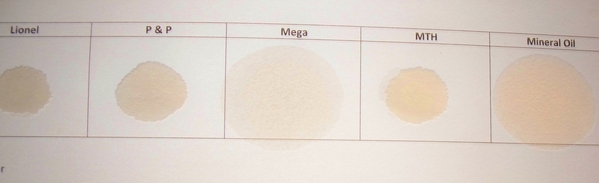

Basically, I used a Lionel plastic pipette and put one drop of fluid on a standard piece of 20 lb. copy paper (kudos to the video by laid off sick where he does something similar). I observed how the fluid migrated and how long it took to be absorbed into the paper. Here are some pictures.

This is within the first minute, you can see that Mega and mineral oil are penetrating the paper quickly.

Here is a close up after five minutes. You can see the pooling of the fluid. Mega is totally absorbed and mineral oil is very close. Lionel, P&P, and MTH still have a liquid drop visible

45 minutes later, Lionel and MTH still had a slight fluid dot that had not been absorbed. Here is the final picture of the paper penetration, held up in the light without the white table background so the size of the drop dispersion is clear.

Assuming this simple test has some relationship to viscosity, there are obvious differences in these smoke fluid products. Mega and mineral oil have similar characteristics as far as being absorbed into paper and dissipating widely. Could this explain why I thought I did not see as much of the filming or meniscus effect with Mega? Lionel, P&P, and MTH are also very similar in that they appear to be thicker and are slower to dissipate and be absorbed into paper. Lionel took the longest time (almost 45 minutes) for the drop not to be visible on top of the paper. Of course, higher viscosity may relate to the longer smoke puffing some have noted (assuming you can get the stuff into the smoke unit) but that is beyond my pay grade.

Where does this all lead? For my two cents, here is the hypothesis: if you are trying to wet a smoke unit and there is only indirect access to the batting, lower viscosity smoke fluid is your friend. Of the ones I tested, Mega steam appeared to work better (or mineral oil) to get the fluid to the batting and avoid filming for locos with complex smoke systems. Use what you want or like after that. As the expression goes, YMMV.