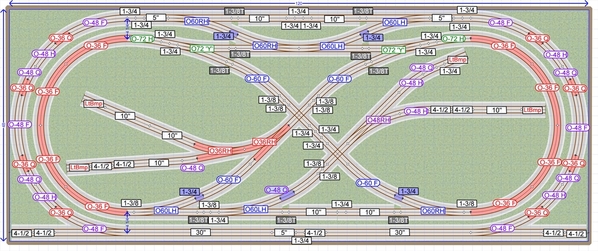

Ken-Oscale posted:With this labeled track diagram showing the 4.25" center-rail spacing.

The layout "closes" at 1/32" maximum tolerance everywhere (most closes perfectly) except the straight section between the bottom right two O60 turnouts (of the three O60 turnouts at the bottom), with that straight section of two 10" and one 1-3/4" being short by about 1/32". Anyway, very close to perfect, and the layout will (should) assemble without gaps between sections, or any compression or twisting of section joints.

As previously mentioned, the track runs right to the edges of the 4x8 sheet, so the outside frame of 1x3 or 1x4 adds 3/4" (1.5" total) to the length and width, giving 3/4" of space for clearance for any cars or locomotive overhang.

The small sections of dark-blue need to have the plastic roadbed trimmed (easy to do), to fit with with the O60 turnouts without the 1-3/8" "fitter" sections at those locations.

It is clear that using FasTrack is not always inexpensive. It is, for many simple track plans, but not for many, like this one, that I design trying to match circle diameters other than the 12" diameters that Lionel give us. The number of turnouts is a cost factor, but one that I do not mind paying due to the high reliability and command control operation option of these turnouts.

Another aspect of layout cost is the number of small straight sections needed. FasTrack is not easily cut into straight tracks of custom width. One can do it, but its hard to get a good and strong joint between cut pieces of FasTrack, with a small gap between the combined pieces. Or perhaps someone has an easy and reliable way, used with success on their layout - I would like to hear about it and see pictures? = Wouldn't it be nice to be able to cut down a 30" section to a 22-3/4" section?

Anyway, in this plan above, there are multiple pairs of short sections, that could be reduced if Lionel made a section equal to two smaller sections - like two 5" make a 10". How about two 1-3/8" = 2-3/4"? Or two 1-3/4" make a 3.5". Or two 4.5" make a 9". My quick count finds 13 pairings that could be replaced. At roughly $5 per section, that would save me $65, not really a lot considering the high costs of O-gauge overall.

Well I suppose the issue is financial. Some cost to set up the tooling, and packaging of the new pieces. But Lionel would sell fewer sections overall. The cost of a 2-3/4" would be only a bit more than a 1-3/8", not making up the revenue of selling TWO 1-3/8" sections. Would more folks build a layout with FasTrack because of these paired sections available - not much. Too bad..., but it is, what it is, as they say.

Perhaps more usefully, I had hoped, that Lionel would produce an O60 curve in half-sections. And a half-section of O96. But I have been waiting in vain. Again, not a big financial winner to produce these. Along with this wishful musing, perhaps Lionel could produce curves in O-45 and O-54. O45 with O36 would produce a double-track in a 4x8. O45 and O54 would produce a double-track in 5x9. No doubt Lionel has considered. And then why not a #4 or #5 turnout?