It must be and I'm not going to build one. Wouldn't be appropriate to be in a rick house under construction.

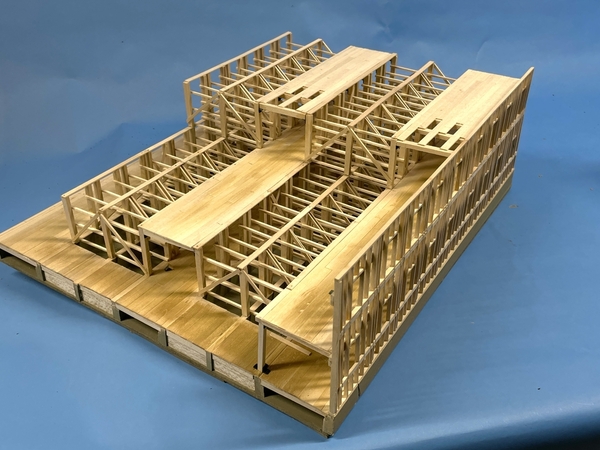

The long wall is fully in place as is the 2nd and partial 3rd-level aisles. I made notches in the 3rd-level joists to fix the misalignment. I started building the front wall and made corrections on the floor ledge positions so all the joists would set on top of the ledge, not next to like is came out on the side wall. "Live and Learn…"

This shows the notching to level the joists. Sorry for the odd camera angle. I also had to splice two of the joists from the shorter 8 scale foot ones to complete this last bit. I used 45° scarf joints to make a nice, clean joint. I don't have many 8 footers left to make some ricks-under-construction for site decoration.

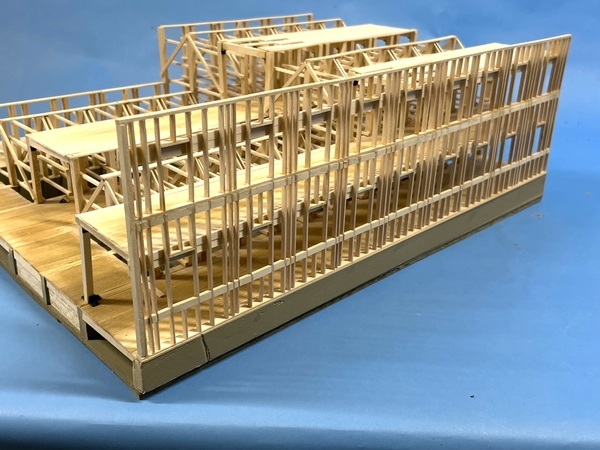

Here are some images of the completed side aisle and long wall.

The wall is surprisingly strong and stable now that the flooring and joists are tying it back to the main structure.

I'm proud of myself. I remembered to set back that lone vertical support in front to accommodate the front wall's sole plate. There will be more supports in the foreground to support that front flooring on the next level up.

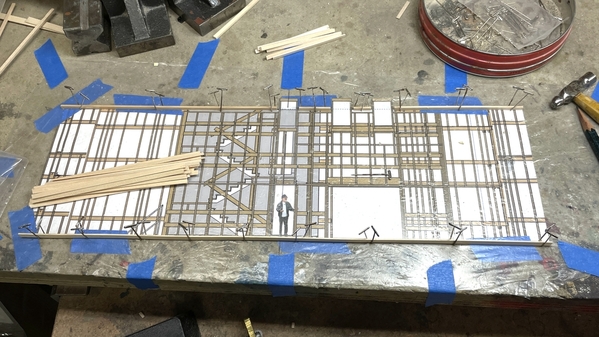

I overlaid the entry hall's plan on the front wall framing since I needed to align them properly. Lying in bed last night I realized that I already made a possible, but easily correctable, error. Notice the interrupted top header pieces. I separated them around the front window openings. This is wrong! Those windows appear on the entry hall front wall, NOT the main building's wall. The header will be continuous on the front wall. Since nothing's glued in place yet, it's a really easy thing to correct. Glad I was thinking about it. Gang cut a pile of vertical 2 X 6 studs in prep for building this wall. Work will start again on Monday.

On another topic: We had a Renewals by Andersen rep at the house this week. We're getting some window work done. Eventually it came down to showing him the shop and railroad. He mentioned that there was a company selling a CO2 laser cutter/engraver for under $500. He gave me the web link. I checked it out. It's not large: 8" X 12" cutting area and 1/8" depth capacity, and would require water cooling and ventilation.

I ran this by my friend who runs the AMIST (Advanced Manufacturing Institute of Science and Technology) at Univ. of Louisville. He said not to get it. These cheap machines are difficult to set up. But more importantly, AMIST is again open to the public and has spectacular laser machines. It costs $5.00 per session plus the cost of materials. If you recall, I posted about my visit there just before the COVID mess started and it was shut down. Now that it's open, I will do my laser cutting there. It's a wonderful resource and UofL's facility is one of the best in the country. It was created as a joint venture between GE Appliances and UofL. Part of the deal was it had to be available to the community. It's one of the best Maker's spaces in the USA.