Mitutoyo is ơn par with Brown & Sharpe and Starrett. You don't need to replace them…ever. Chinese $20 calipers wear out every couple of years.

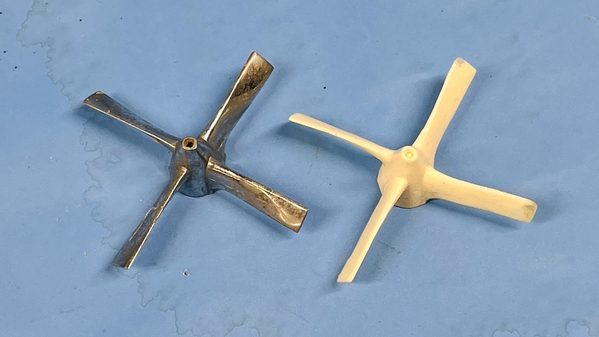

Potpourri day. Working on the billboard, and the turbo-prop propeller for the L-188 restoration project.

Building a silicone mold without applying mold release before pouring the top half is a terrible boo-boo. While I was literally able to rip the mold apart, it destroyed the clean parting line making a mold that works marginally at best.

But persistent me tried another pour after opening up the vent hole where the previous air pocket was. It did make a propeller. It needed some added work with Bondic to make it whole, but as a test article it was a good proof of concept. It's not perfect and a bit warped, but it is a propeller and closing matches the master.

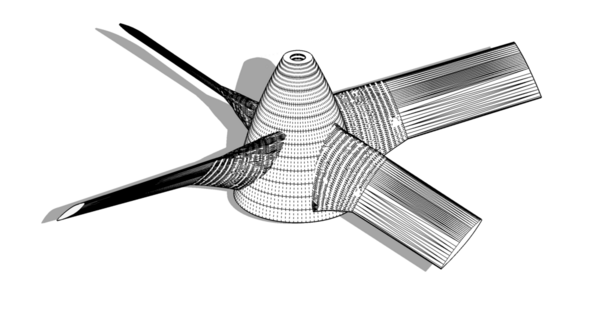

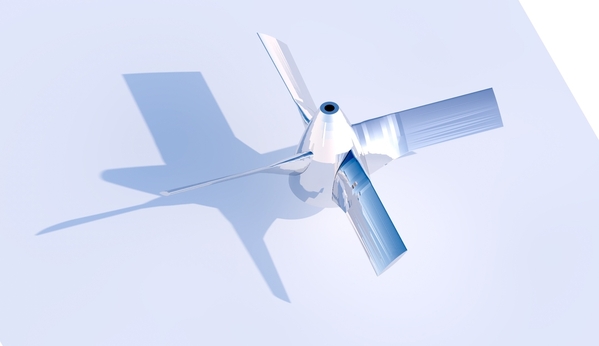

But, I'm also working on plan B. I decided to try and 3D print one. That required drawing this propeller in scale on SketchUp. It was one of most difficult things I ever drew. The blade changes sizes in three directions: twists, gets thicker and tapers wider near the root. SU is not happy with shaped surfaces, but it technically can do it.

Here's the finished drawing showing all the edges and polygons on its surface.

The drawing is made up of a series of formers or ribs, just like an flying RC model. And like a model airplane build, the ribs have to smoothly flow from one to the next so the skin on the surface is also smooth. The tool to do this is the SANDBOX. There are a couple of options and the one I use is "From Contours" Theoretically, the skin should form cleanly going from rib to rib. But that's not exactly the way it came out. Instead, the skin formed in a series of layers going at right angles into the shape rather than across it. I had to go back and remove any errant layer and then hand build the skin drawing a series of triangles from the nodes on each curve of each rib. It took hours. Twisting the parallel portion wasn't hard. You extrude the length from root area to tip, pick just the tip and rotate it. With the root end fixed, the entire blade twists perfectly. The root area was an entirely different animal. Here I had to start with the largest shape at the root, copy it and move the copy forward along a pre-drawn guidelines that had both the twist and bottom taper, and then scale each rib smaller than the last as I moved towards the parallel section. Then I had to clean up the mess from all that errant skinning. I worked a couple of hours yesterday and three more today, but…. SUCCESS. I looked at some videos to see some of the techniques, but in the end I had use pure muscle to clean up the mess.

The end result measures within a couple of thousandths of the overall diameter of the original. I used my digital caliper to measure all the key metrics to build it. It's now on the printer and will be done in an hour or so. I noticed one corner of a blade has a missing chunk, but that's all correctable with Bondic.

If the printed versions work, I may stay with that. If not, I will re-mold the prop and cast more using the low-melting point alloy so it will be real metal. I know what I have to do with the mold to make a better part. It's hard to get some of this stuff right the first time around. I'll post an image later when it comes off the printer. And I will remember to use mold release!

I've purchased and am in the process of installing a removable, flexible, magnetic build plate. It's magnetic stainless steel that is quite thin. When you take the plate off the machine, you remove the thin plate off its magnetic back plate and flex it to pop all the parts off WITHOUT scraping with a razor blade. It saves time, saves parts and saves fingers. The magnetic portion is held to the existing build plate with a very strong 33M pressure-sensitive adhesive. I had a new build plate that wasn't using so I was able to install this new upgrade while still printing. You have to let it set over 24 hours before exposing it to raw resin. I'm interested in seeing how this baby works. This image doesn't tell you much. It's just a nice shiny plate sitting on my photo table. Without scraping, the binding surface will remain in much better shape.

While all this was going on, I finished up the second billboard frame, added the graphics and glued on the posts. Next session, I'll put some cross-bracing on the leg bottoms and it will ready to install on the rick house site. The graphics are very glossy and wouldn't be in real life so I'm going to use some matte coating to kill the shine.

Tomorrow a.m. I'm probably going back to the sheet metal shop to get the L-188 stand welded. When I get home, if there's time, I can finish the billboard and start working on site rocks and ground cover.

Later this week we're heading back east for a wedding celebration, and will be there for next week until the following Saturday. And I still don't have my self-driving Tesla… drat!

On another front, I am not happy to wax political, but this needs to be said. I got a text from my hairdresser last night cancelling my appointment tomorrow due to the fact that she's tested positive for COVID-19. What makes this so noteworthy is that she, and her partner husband, and he son (who all work in the salon) refused to get vaccinated, wore masks only when they were forced to, and generally came up with more bullpoop reasons for this behavior. What makes matters worse, she's 60, immuno-compromised, has RA, takes Humira, and generally has trouble with colds and flu. Her husband is a smoker.

My daughter, wife and I have used this salon for over 12 years, and the person considers me an intelligent person, but I couldn't get through to her that she was simply playing Russian Roulette. She has a 2 year-old granddaughter who she watches a couple days a week and her youngest son is expecting his first child imminently. All of this in now in jeopardy. With her pre-existing conditions, she is a person who could have a terrible if not fatal case. She's had other vaccines in her life, so all the rationalizations were just that… nonsense. She was also putting all of her clients at risk, including a spry women who just turned 101.

To vaccinate or not vaccinate is not a right of choice! Your decision does not only affect you. It affects everyone you come in contact with, love, take care of or are friends or co-workers with. If you choose to smoke knowing full-well the consequences, and you die from all the crap smoking can do, you don't kill other people in the process. If you want to ride a Harley without a helmet, you won't survive a spill, but your head isn't going to kill anyone else. Spreading a highly infectious, killer disease is a different ball game. It's like thinking you have the "Right" to drive down the wrong entry ramp on the Interstate and drive into on-coming traffic. In that case you will kill others besides yourself. Time to get back to real life. If you are not vaccinated, DELTA will get you. It's just a matter of time.