Thanks.

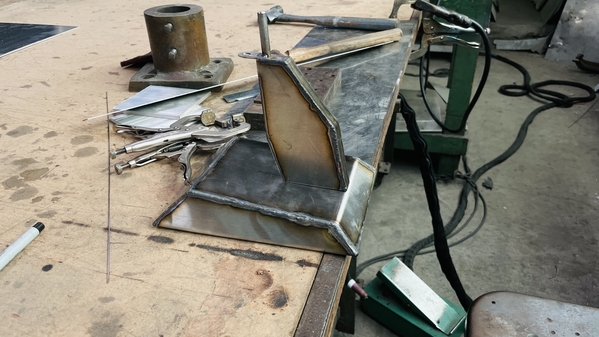

Got a terrific stand finished today for the Elektra. I cut and bent most of the pieces and Jim, the welder, at Gettler Sheet Metal, did a masterful job closing all my ridiculously bad joints. Bending 18 gauge stainless isn't my forté and I didn't have bend allowances built into the plan. Bend allowance added dimension needed as the metal stretches to accommodate a bend. The sharper the bend and/or the heavier the gauge, the more stretch. It's not much, but it can add up. To make matters worse, while my design was cool, it was also difficult since there wasn't a right angle in the entire design. Regardless… we did it.

Before closing up the base we welded about 5 pounds of steel plate inside to counterweight the whole deal. By boxing in the upright, all the movement in the yaw direction was eliminated. It is very stable. We cleaned up most of the welds at Gettler's and I have a few more to do in my shop.

A 1/4-20 cap screw holds the plane solidly to the base.

Additionally, there's a 5/16" stainless rod welded to the stand that slides into the other hole on the plane's belly. it's not going anywhere.

I added four silicone feet to the bottom to make a nice, scratch-free structure.

And a perfect prop just came off the printer. I started using the Fulament flexible, magnetic build plate and it works pretty well. The part didn't pop off as shown in the video, but it did pop all the edges free so my plastic scraper slid right under to remove the part. I like it.