Thought you'd all like a progress report on the Newtown Hardware House project. I contacted the manager of the store and he took some more detailed pictures of the building. He was very interested in it. Our Philly friends also know the owner of the store and she wants to share the project with her. They may want a model of their own. The brickwork on the facade and particularly the pediment is pretty complex, but after my distillery project experience, I know exactly how I'm going to lay it out for laser cutting. I will 3D print all the cornice details including 3 different corbel styles. The sides and rear aren't very remarkable, but the first floor windows have shutters. I can buy the self-stick laser board from Stephen Miley at Rail Scale models. The walls will be 1/4" MDF. I think the stone lintels over the windows will be laser board and I may try and engrave some texture in them. I could also 3D print them with the texture. We'll see… Each project that preceded this one gave me the experience needed to master all this nuance.

This is a view of the real pediment. Notice the different levels of relief on the various brick details. I still have to put in that round window. Don't know what the mullions on that one are since a tree blocks a direct shot from across the street. We're going to be back the area over the New Years holiday and the tree will be free of leaves so I'll be able to get a better shot of it. You can also get a good view of the lintels in this image. There's three kinds of dentil molding in that front as well. Like I said, it was more complex than you originally think.

The Seahawk project is coming along. I've purchased aftermarket resin kits for the right T700 engine, main rotor, tail rotor and the hinge assembly for the folding tail boom.

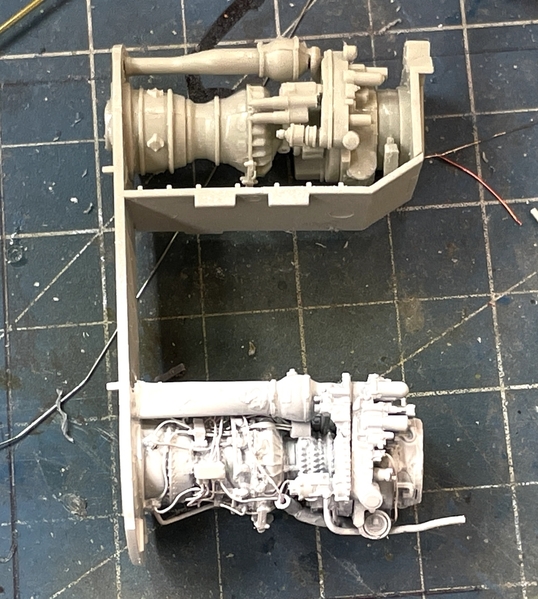

The engine took a week to build with all the added piping. It was worth it. The top one is the kit engine that will not be exposed. The bottom is a ResKit model of the GE T700 turboshaft engine. Painting this will be fun.

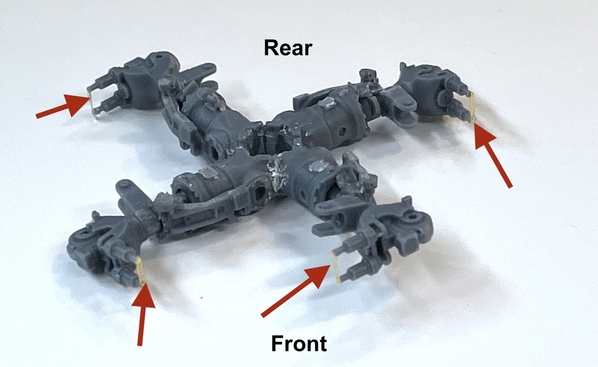

I'm also building the main rotor kit and it's just as complex and challenging as the engine. It too will add a tremendous amount of interest in the build. What you see hear is already 16 pieces all glued together with Gel CA. There's a large amount of hydraulic lines that get added to this. The naval version is more complicated than the Black Hawk version due to the requirement to fold the blade while onboard ship. Those twin pins you see are hydraulically actuated to insert steel pins into fingers on the blades to lock them in the operating position. When the blades are locked, the pins are in and can be detected easily by those brass straps being in the "in" position.