I'm almost finished the Hardware House drawings. All that's left is changing the trim under the front store windows. It was a bear to draw, but it's pretty close to the real thing. I'm also making progress on the SH-60B Seahawk. Piping the main rotor was also a bear and tested my mettle to the max. Still have two tiny pipes to add that I missed. No one would know.

Three different corbel and dentil molding designs in one building front….

For reference, here's the back. I'm not sure how to handle that scary fire escape. Notice the 6 X 6s holding the whole deal up. Tichy makes a fire escape set in styrene which I think I already bought. It could be printed, but it wouldn't be easy. Might be easier to solder it together out of brass.

The real site sloped back exposing more of the basement in the back. Mine is flat so I'll be using a different basement entrance.

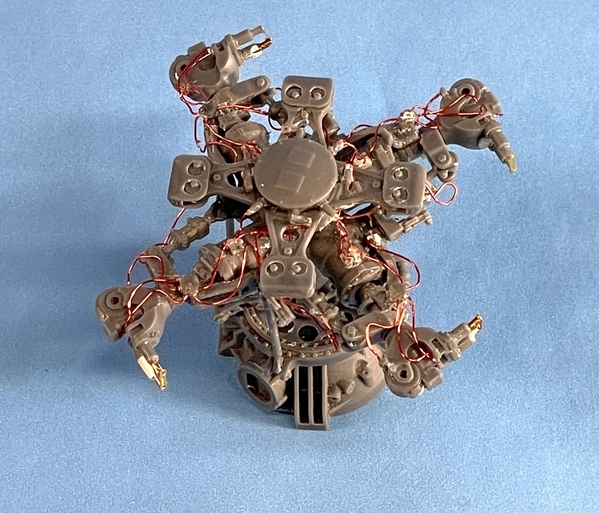

Here's the rotor head. All the wires are magnet wire (less than .3mm) and are in 0.012" holes.

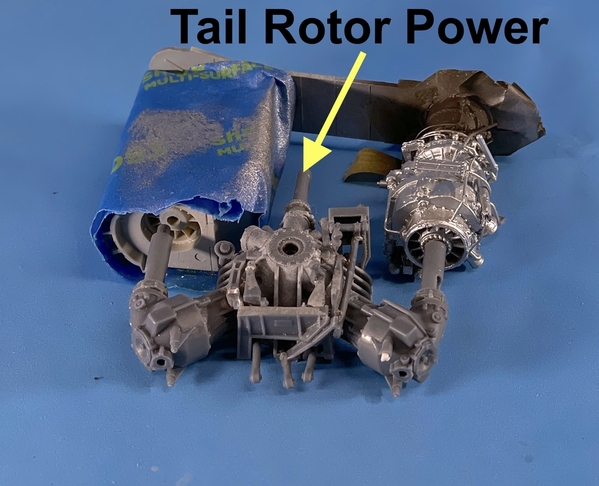

The transmission is just as complex without all the hydraulics.

The real one… All the complexity under the mech's feet in the hydraulics bay IS NOT reproduced in the model nor will I attempt to do it. Those floppy weights on the ends of the four arms in the picture and my model is the Biflar vibration damping system. Those weights are tungsten and they move freely about an axis acting as a pendulum that cancels at the source rotor induced vibration. It reduces in-cabin vibration by 55%. The fact that this is a Navy bird drastically increases the complexity of the rotor head to enable the rotor blades to be folded (as they are in the image). Both the swinging of the rotor to the stowage position AND the locking of the blades in the fly position are hydraulic and remote controlled. One more pipe to add when the blades are installed is the nitrogen crack sensing system connection. Blades are hollow and nitrogen filled. It there is a crack, nitrogen leaks out and is sensed. It sends and alarm to the cockpit to immediately get the blade changed.