I bought some more tan paint from THD and painted all the foam and Sculptamold so it would provide a more "realistic" base for the all the yard ballast. I then finished up the feeder track into the yard with the regular ballast and alcohol/water mix, but then converted the tail end to the mixed yard ballast and the weathered wetting agent.

I'm using a mixture of alcohol/water and a couple droppers of India ink for the yard wetting agent. It dulls it down a bit.

Here's the painted areas. It already looks better without the pink foam showing.

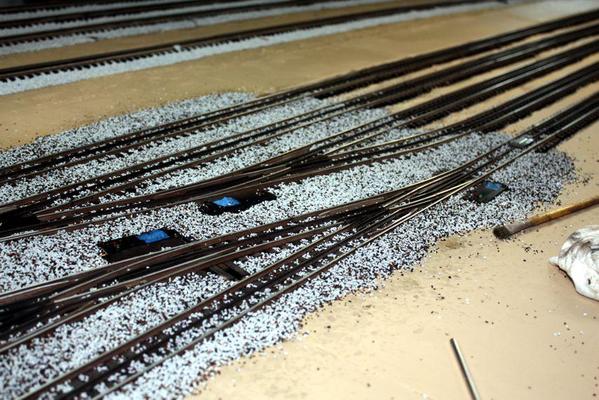

The yard ballast mix is the white roofing granules, W-S coarse cinders and W-S coarse brown ballast mixed in relatively equal proportions. I'm just filling up the track areas to start. The foam is slightly higher than the track ties so the very outside ballasting is a little fuller than the between-tracks ballasting. Again, it's a hassle to keep the stones out of the switches. I finally resorted to putting some masking tape over the manual control opening.

It's still a bit bright so I may go back and do some more air brushing and weathering of the tracks.

This first picture shows the ballast piled up before spreading. Notice how much brighter it is than the glued area to the left. That area has been treated to the India ink treatment.

And here's the track after spreading, wetting and applying glue.

I have to leave a cavity surrounding the elongated ties that protect the moving points slide. I use a small brush and a tweezer to pull out any errant stones. The ballast on the edges is now level with the foam. I have to decide what kind of ground cover I'm going to use for the rest of the yard.

I have a problem with my Gloor Craft coaling tower. It has the wrong track spacing to cover the two tracks for which it's designed. The outside track would be under the coal chutes, but the track running inside should be where coal is brought to the station. When I put it on the track it's just too tight. I can put it on the outside, but then there's no track to bring coal. I'm not going to spend the money for another Ross switch to create a spur to feed it, plus I don't have the room for that track if I want to have space for the water tower and sanding station.

It's the catwalk that's causing most of the problem, but you can see here that this station is design for at least a 5" track separation. As it is now, the chutes will dump their coal into the inter-track area next to the tender. I can make due if I remove the catwalk or raise it above the height of the tallest locomotive (4" or 16 scale feet). Or I could design and scratch-build my own to accommodate the 3.5" track spacing created by laddering the Ross #4s. Or I could use this tower as a basis and kit bash one with the correct spacing. Any suggestions?