Mike, I believe you... your the first reader who responded three times in a row.

I wasn't in the shop for a couple of days so I did some more design work on the laptop. I'm thinking that after the train station, the engine house would be a good next project. I planning on using 3/16" foam core and brick paper so the cost will be low and size can be large. I printed out my first attempt to get an idea about size and fit. It's printed from CorelDraw in tile format, taped together and mounted on some cardboard. Here's the mock-up set on the layout. I'm forced to scratch build this structure for two reasons: my yard track spacing is 3.5" as a result of using Ross #4 switches, and I have very long engines. One could buy two or more commercial kits and join them end to end for the length, but no one makes one with this door spacing.

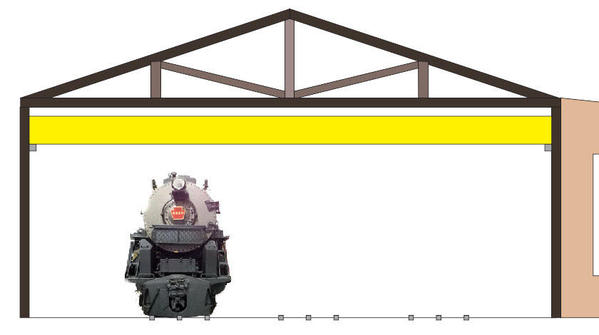

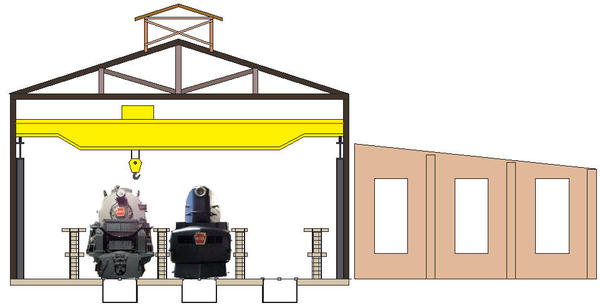

As a result of this test, I'm going to add another inch or so to the length so the bumpers lie within the building. I'm also adding more width so any vertical columns have sufficient clearance from big engines. Speaking of big engines, here's what it looks like when 36" of Pennsy S-1 is stuffed inside. That's the biggest engine that can practically make it. The coal turbine, the Centipede, 3 units of E-8s and all four units of my F-7 diesels are all too long.

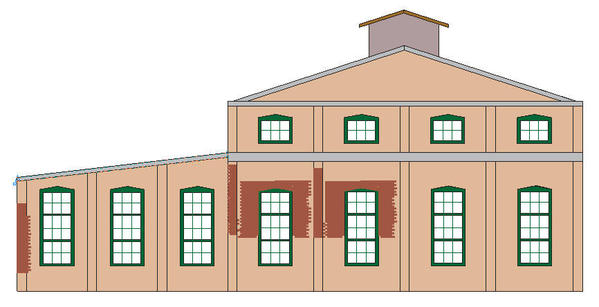

There's room on the front facing side for a machine shop so I've now added that.

Lastly, I've started designing the truss system. Here's my rendering showing my Pennsy J1-a inside and a simple overhead gantry crane sitting above. The "J" is 16 scale feet tall (as are all the big engines) so it takes up a lot of the overhead In my estimation, the height could to be at least another 8 feet or else the crane would be pretty useless. Since nothing has been cut or glued, there's time to make all these changes. And using brick paper which I'm printing and foam core, this doesn't affect cost much. Also needed are work platforms and inspection pits.

I've subsequently designed a taller structure and also toying with adding a clerestory roof atop of the main roof. It complicates the interior structure, but makes the building more interesting. So here're modified views of the raised building. I need crowd input here... I can often design more than is practical to build with my budget, time and skill.

3.5" spacing doesn't leave much room in between for work platforms. In the above pic the platforms are just about 2 scale feet wide, so may be impractical. I'm also showing the inspection pits. At first I thought these would be impossible with 3R track, but have seen some Forum members use clever workarounds such as stretching bare copper wire across the middle which is almost invisible yet carries current to the pickup rollers.

There're many windows. I'm going make versus buy. This lends itself to jigs and fixtures. Styrene strip stock is cheaper than a couple dozen Grandt Line or Tichey Group molded windows. Also missing from the drawings are smoke jacks, vents and stacks that will be in the finished model.