That sounded like fun...;-). In my college years, I spent the summers working as a mechanical technician at American Electronic Labs. They were a sophisticated contractor making military communications and electronic counter-measure equipment. In their lab they had an anechoic chamber where they tested antennas and detectors where no extraneous EMF could get in. The door, like you Farraday cage, had copper fingers that made a completely EMF proof. The walls were line with those black foam pyramids (facing outwards) that absorb all kinds of radiation including sound. The room was so quiet, all you heard was your blood hissing in your ears. Now that I'm older I hear that hissing much more than I would like (too many years playing electric guitar and running engines and machines...).

Got a late start today. The days that I work out I don't get to the shop until later in the afternoon, but I did get some stuff done.

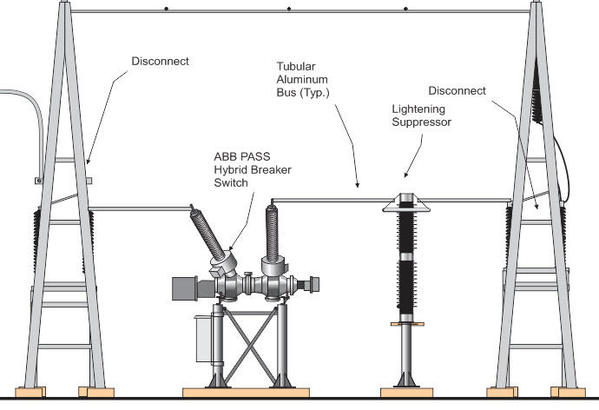

First of all, I'm doing more research on the switch yard itself and was looking for different designs of the various components and found these Hybrid units by ABB. They have the breaker, earthing switch, current and voltage transformers all built into a single, interesting looking unit. Some had 3 insulators per phase and others had two. The difference, I learned, was the 3 insulator version would span between two feeding buses and would switch to the other instantly in case of a fault thereby ensuring no break in service. Since I am not having a dual bus switch yard, and will only have one power transformer, I'm going with the simpler version.

Even though the actual building of this ABB Hybrid PASS as a model might be challenging, not having to build all the other separate components will ultimately make it easier, or so I'm hoping. These units were designed specifically to outfit substations where real estate is scare. Nothing describes a substation on an O'gauge RR better.

I'm also going to go with aluminum tubing bus bars instead of wire since I think they'll look better at 1:48 than simulated wiring. Here's the new design with my rendering of the Hybrid breaker.

Even its base is simpler since it has only two legs supporting all three phases with some channel spanning all three.

After drawing all those intersecting tubular objects to make my working drawings, I realized that I could scale the PDF and print it at O'scale right out of the printer. The ABB print showed a scale of 1:40. I assumed that this wasn't a copy of some other larger drawing. So 1:40 scaled up to 1:48 is 120%. I set the printer to output the PDF at 120% and voila! It came out within a half of a millimeter over the stated fulled size dimensions. BTW: the dimensions are all in MM. I've included the actual PDF.

I put this all aside and got back to the transformer which is far from finished. I shaped and attached the 8 lifting lugs on the tank. I didn't have strip of the correct size (0.187" X 0.080"), but I did have 187x40 so I glued the strips together to get the thickness I needed and when dry, drilled, cut, and filed the pieces. I then measured the MTH transformer lug locations and transferred them to the new tank and glued the lugs on.

When they're set nice and strong, I do some light finishing around them.

When they're set nice and strong, I do some light finishing around them.

The side opposite the radiators needs an array of lighting suppressor towers that are supported by a set of brackets, channel and cross-pieces so I had to make more brackets. I won't detail this task since you all know what it entails by now. Here they are with the hypotenuse still needed to be sanded off.

When fully dry I'll sand of those little tails, locate and attach them to the tank.

I was also expanding my reference library of transformer pictures to do two things, determine the best kind of bushing mounts for the transformer, and understand what kind of surface details and simulated wiring I want to add. Some of the surface detail on the MTH transformer may work, but I not sure.