I hope your faith in my skills is not misplaced. The locos were fine, but I need to do major work on the loading dock. Thanks again to Ashe Rawls for convincing me to never glue building into the layout. All I have to do is disconnect the two leads for the lighting and the entire structure with its base lifts right out. This lets me make any repairs at the work bench instead of laying across the layout.

I'm gong to have dams. I don't want any PCB spills on my layout.

Today, while it wasn't a particularly long session, but did see some progress. All the primary bushing bases are installed and I'm doing some work on the lead input ends of the insulators.

I wanted to add some aluminum doodads on the insulator lead ends. All of the ones I've viewed have some kind of aluminum structure to hold the primaries and guide them into the insulator. I turned down the tapered end of the "insulators" to a nominal size about 1/8". It's Delrin (or some other engineering plastic) and doesn't machine really well. Regardless of the final size, I just select a drill that fits. I use my number drill gauge to final size the turned end so the finished cap just presses on.

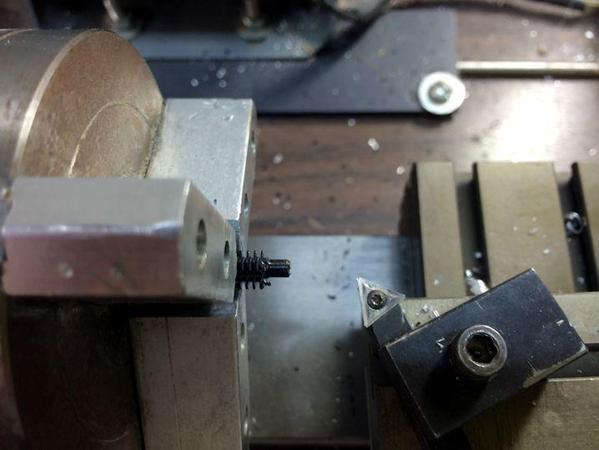

I turned the bushing tops down to about .265" which is the o.d. of the "insulator". I face and drill one end. The depth is measured directly from the turned end of the insulator. I tried making a formed cutoff tool that would both cut the piece off the aluminum stock and also impart a domed top. This didn't work so well since it kept binding and stalling my little lathe. So I used my regular cutoff tool and just stepped it towards the headstock a couple of times as I was penetrating the work so the final surface had the look I wanted.

I finished two and the third is still in the lathe waiting to be finished. I think I'm going to leave the insulators black so the discontinuous nature of these body screws is less noticeable. What to you guys think?

I'm going to do the same thing to the breaker and suppressor insulators. I'm also going to add aluminum rings at two locations in the lightening suppressor stack. Having a lathe is great! I'm also thinking about getting a new air brush compressor. My current one is 37 years old, and is a simple diaphragm compressor with no pressure regulation or reservoir. It's done yeoman service, but it's really not sufficient for the kind of work I want to do. I also want a spray booth. Santa's going to be busy this year.