Boiler progress was made today. The second foundation has its feet. I started to build the front end detailing. This involved a sequence of round disks applied to the boiler front, and then constructing a series of drums that held the burners and air heating units. Here's both boilers sitting on their frames, neither is glued.

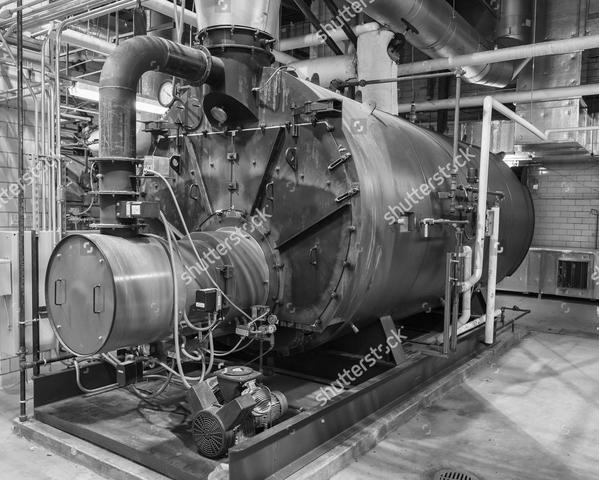

Here's the best image I found showing this level of detail.

There's a ton of detail to add including lifting lugs, hand holds, clamp-down bolts, and lots of bolt and nut details. To make the round pieces out of 0.010" styrene I use my homemade circle cutting dividers. I had a second set of machinist dividers that I ground on needle point to a chisel point so it can scribe styrene sheet and make precision circles.

While it works great, I have to be careful to apply very light pressure as I rotate the point. If I press too hard, the chisel point starts to track inwards and distorts the circle. About three rotations are sufficient to produce scribes that are deep enough to snap the styrene. I'm using thin material. If you're doing this with heavier stock, then you'd have to do rotate it more times.

There's a large plate that represents the removal front plate. Before installation, I used a center-finder on my machinists square and found the center. I then laid the boiler on a pair of v-blocks and using the square on a piece of plate glass, drew a center line. I did the same thing on the plate. After placing the centerlines together, I applied solvent cement around the edges. Below this goes another disk that represents the burner location. I estimated that this was about 1/2 the diameter of the boiler. This was convenient because the only large tubing I had besides the 2" pipe, was some left over 1" PVC pipe which made nice drum material.

On this goes some reinforcing ribs which I made out of 0.080" Evergreen Styrene angle. I laid out the lines with a machinist's protractor. First I needed to scribe a horizontal datum line across the center of the smaller disk. Then I laid out four lines; 2 at 30° and 2 more at 75°. The angle was glue with solvent cement.

The outer drum has a rim around the face. I simulated this by using a smaller disk and a rib of 0.020" X 0.080" strip stock. The ends were held with CA, the rest with solvent cement.

Behind this large drum is another one. Between them is the burner assembly and is also flanged. In this case, I didn't have a piece of round stock so I'm turning one out of aluminum. If I had more tubing choices, I would have made the tube and attached a disk on the end to simulate the flange, but I didn't so machining was the way. To cut the drums squarely, I first scribed the length using a surface gauge. Then using a coarse toothed razor saw, carefully cut on the line a bit, rotated the tube, cut a little more, and so on until I was able to cut through squarely. A little touch up on the belt sander and then on some medium grit sand paper on the glass plate and I have flat and square ends.

Here's the four drums completed with their respective end caps CA'd on.

And here's the stock in the lathe. Notice I'm working on both ends. The end in the chuck already was turned down to the diameter I wanted (0.650"). I drilled through the whole piece with a 1/4" drill which will support the 1/4" tube that's going to align an hold the three pieces together. In this picture, I'm in the middle of parting off the first piece. Instead of turning the piece around and parting off the other, I'm going to leave it in the chuck and just face the remaining stock off until I have a thin flange. I'm doing it this way because, I won't be able to get close enough to the piece with the cutoff tool and still have enough material in the chuck for safety. I may reverse the piece being cut off and face its flange down so it's even thinner.

Weekend's here so work will begin again on Monday... that is unless I get to work when my grandsons are here. No 1 grandson has a couple of projects in the basement that he could/should be finishing. If he wants to work there, then I get a chance to work too. Otherwise, see y'all Monday.