Thanks Mark! As I said, with the finger, I'm quite able to do all my modeling, it's just making it difficult to play guitar which is a bummer since I just got that Gibson only last October.

Now onto today's efforts...

First thing I did was fabricate the smoke box door hinges out of brass. I didn't have brass channel small enough for this, but I did have a piece of K&S square tubing. I cut one face out to make it into a channel, then drilled an 0.032" hole through the sides, inserted a piece of brass wire and added some small brass channel. This was soldered with the RSU and 60/60 solder. Then, after cutting the channel to a specific length, filed the very end with a little notch and soldered another piece of wire using the TIX lo-melting point solder so it didn't unsolder the previous joint. In looking at this picture, I realize that I CA'd the hinges to far inwards. In the prototype, they stick out of the side. I'll try and reposition them tomorrow... or maybe it really doesn't matter since it's going to all be buried in a building.

Next up was bending some wire grabs for the front and installing them in 0.021" holes. I bend the grabs in my long nose pliers after making a mark with a Sharpie so I could position all the subsequent wires at the same place in the tapered jaw and produce equally sized grab handles.

I bought some 1/2" o.d. brass tubing at the LHS yesterday for the transition tubing to the big flue pipe. The PVC pipe i.d. was just a scosh to small so I had to bore it out a bit on the lathe. I had cut the PVC to length with a razor saw and my small miter box and took the mounting in the lathe as a chance to also square up the ends. After boring it accept the brass, I had to also cut the brass with nice square ends so I did the tin the lathe too. I used the steady rest on the outer end so I could support the 12" length of pipe on my tiny lathe. If it was a larger machine, I could have put the tubing through the chuck into the hollow headstock spindle, but this machine's spindle only has a 1/4" hole through it. With two boilers to make, I had to make two of these assemblies too.

The prototype has that pipe running from what looks like an air filter housing to the exhaust flue. In thinking about what that's all about, I realized that it's probably a pollution abatement line to recirculate some of the exhaust stream and reduce emissions. Regardless, I liked it as a detail and was going to add it. I've solved the bad fit of the T6 components to the T6 tubing. I drill the center of the T4 tubing out to the correct side for the pins on the T6 fittings and then glue the T4 pipe inside the T6. This makes a nice tight concentric fit that needs very little adhesive, although it does add a bit of work. I drilled the big flue pipe to accept the T6. And after sizing the length of the pipe added an elbow and a vertical pipe to join a hole drilled in the air filter housing. I drilled that in the drill press with the housing held in a V-block so it would square and centered. The prototype seems to have some controls and instrumentation added and I will do some work in that area too. I should have added it before gluing the first assembly together, but I figure something out. The flue is held to the flue adapter with medium CA. I may wrap the flue with aluminum foil after painting to simulate the insulated jacket.

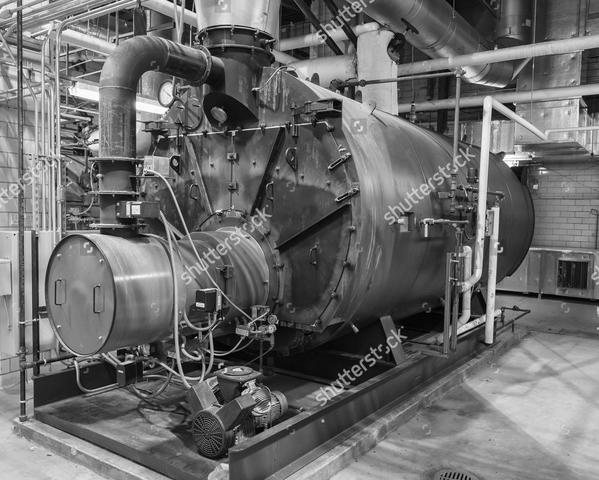

Again, for reference, here's the prototype upon which I'm loosely basing my rendition. My proportions aren't the same. It looks like this boiler's casing is not actually a circle. It appears that the top is ovoid in shape. You can also see how I mis-mounted the hinges. I printed out this pic, but it was upstairs and I was going from memory. Big mistake. Regardless, the model will have the right feel of an industrial setting and will nicely fill the boiler room. I'm going to add some NDWs to the filter front too.

My building couldn't have handled anything taller so I was to use this boiler's full height it may have been too tall.