Checking in again...

Glad I kept the plastic sheeting over the city until the new dishwasher was installed and checked out. I went to remove it last week after the dishwasher install, but noticed water in the Rubbermaid pail and on the plastic sheeting. We had the plumbers remove the old dishwasher and waited over two weeks for the new one to be delivered. Meanwhile, the stop valve under the kitchen sink that was "shut off" after the old dishwasher feed line was removed was actually leaking a a little bit. Just enough to wet the area under the sink AND to seep down the pipe and come out of the basement ceiling onto the layout AGAIN. All is now dry and I'm going to remove the sheeting and run trains again.

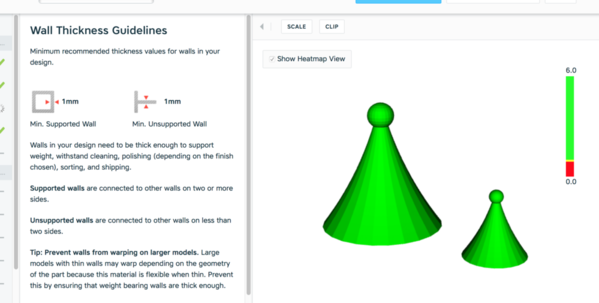

I'm still working on the Nighthawks design to make it a DIY project without laser cutting. I've adjusted all the exterior dimensions so it is no larger than 6 inches wide and deep so I can cut two sides out of a single sheet of Evergreen 6 X 12" stock. Further I thought about having the two turret cones produced by Shapeways and redesigned the geometry for 3D printing. I sent them the converted-to-STL SketchUp drawings and was ready to pull the trigger. It would cost $44 for hi-res acrylic printing. That cost is not out of line, but then I thought about how to make it in my shop for $0. It's about 2 inches in diameter and height. My challenge was my little Taig lathe. It isn't really a wood lathe and I can't grab a four-sided wood chunk in its 3-jaw chuck. I thought about how to approach this and came up with a solution. I will create a square blank (which is now being glue downstairs). I will drill it in the approx. center and then glue in an appropriately sized dowel which will go into a 3-jaw chuck. I will carve off as much stock as possible before putting it in the lathe and then using a sanding/grinding bit in the Dremel and grind off the wood as the lathe is turning. This way I won't have to use wood turning tools (which I don't have) nor use a wood turning tool rest (which I also do not have). Should work. Here was the set up screen on Shapeways.

Another possibility would be to make it out of Scuplty hardening clay.

A third possibility would be to make it out of modeling clay, make a silicone mold and then resin cast it. That's not a cheap solution since the resin materials are not free.

There's a dense foam called Renshape that makes a great carving foam and is available at https://www.freemansupply.com/...g-and-styling-boards

I believe it is NOT inexpensive.

I'll keep y'all posted.