Thanks Mark!

So... I'm ordering a sample pack of Renshape from Freeman. It's $25 and gives chunks of all different densities of their structural foam and other pattern making materials. Considering the small sizes of the pieces we O'scalers make, that sample pack could be all I need.

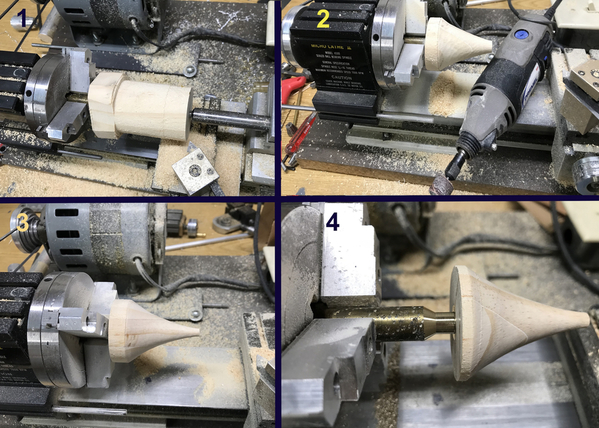

Meanwhile... I decided to see if I could make the turrets from wood. I have wood and I have a lathe (although not technically a wood lathe) and figured "what have I got to lose". The glued up block was really a bunch of angular cutoffs from layout frame building so first I had to knock off the angles on the chop saw. The first time I tried to cut it, it promptly flew off the back of the saw table. It was a tall piece (almost 3" high) and hand holding it was stupid and dangerous. Didn't get hurt other than surprise. I then clamped the block against the fence with another piece of longer stock held with a c-clamp. This worked well and I had a cube of solid wood very quickly.

I found the centers on each end and drilled one end in the drill press to accept a piece of 1/2" brass rod. After inserting the rod I soaked the end with thin CA so it was very secure. I sawed off the square sides to reduce the overall shape to sort-of an octagon using a Japanese style thin-blade hand saw.

This I COULD chuck in my lathe. I also drilled the tail end for a tailstock spindle to stabilize this big chunk of wood. I took it nice and easy using a metal working carbide bit to gradually knock off all the high spots and create a true cylinder. I then proceeded to gradually reduce the diameter of the small end tapering it to the large 2" end. I did 2-hand turning which is always fun. I moved the carriage feed with my right hand and wound out the cross feed in an ever increasing speed to create a cone with some curvature built in.

When it was near net shape, I used the Dremel with a sanding drum while the lathe was turning to create the final shape. I had a template of the turret that was drawn in CorelDraw which I printed out and pasted to some illustration board. After using the Dremel I hand sanded the turret to smooth finish.

The last thing I did was move the piece further out of the chuck and face the back side so it was true to the cone AND reduce the brass plug diameter to 3/8" to make less metal to part off. I used a hack saw to cut it off since there was limited room to get in there with a part-off tool.

The process to create the small bottom turret was the same, but easier since I didn't have to glue up the block and had less wood to remove to create the octagon. Here is a picture of what it looks like after the 2-hand turning.

Again I cut off this piece using a hack saw, only this time the plug was aluminum. After finishing, the small turret looked like this.

There was a scratch in the large turret that I filled with Tamiya filler putty and then sanded smooth in the lathe.

Here are the two turrets fitted with ball bearings that I conveniently had in an old film bottle in one of my drawers for years. I had two of almost the perfect size. I'm going to coat them with Tamiya clear color coat so they'll look like mirror balls. I epoxied the balls in place and will let dry overnight.

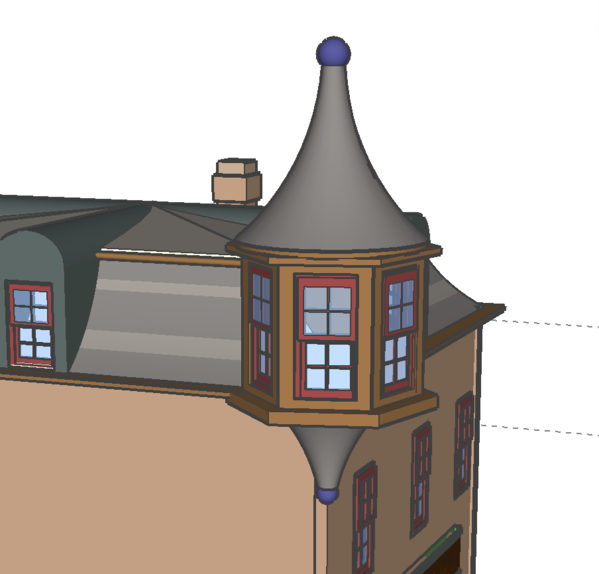

To refresh you memories, here are both turrets in building on SketchUp.

The turrets were the most challenging part of this build (IMHO), so having them done first really relieves some stress. The rest of the build is more straight forward and is a repeat of other kinds of builds that I've done. In practice, these kinds of architectural details are shingled with shingles of decreasingly smaller size as the diameter shrinks going up. I've had thoughts of buying Rusty Stumps HO and N scale shingles to do it, but it's a lot of $$$ just for a few fractions of inches of shingles, so I may cut my own out of the straight Rusty Stumps O'scale shingles I have in my stash.

Another wrinkle is the lower current is embedded into the building's corner. I may be easier to cope out the building to let the turret nest into it, then try to cut out a quarter of the wood turret. It's not the wood that the trouble. It's the big aluminum pin embedded into it that will be harder to cut, AND there's no convenient way to hold it. Since I had a cutting template of the shape, I can trace it onto the building and simply cut out the profile.