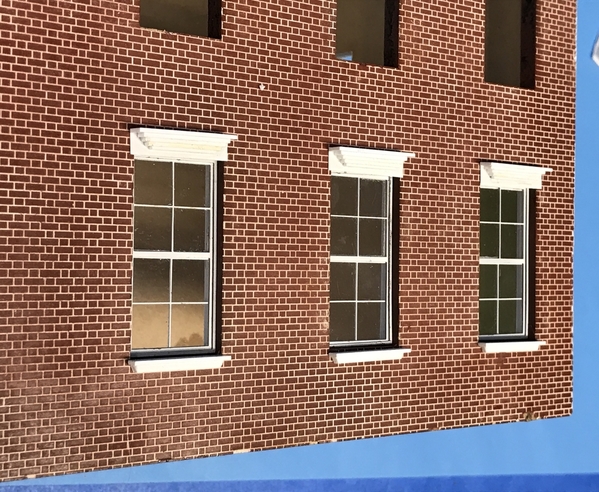

While I could have built more windows today, I was itching to get to building all the molding assemblies since this is such a focal point of the building. I finished scratch-building the 1st floor's window trim and then went to work on all the 3D printed stuff. I'm very happy that Rusty Stump's resin is very tough and you can sand it without worrying about it falling apart.

I may have overdone it with the amount of trim over the first floor windows. Before I glue them in place permanently, I'll re-evaluate, and if necessary, build them again a bit smaller. Nothing is glued down yet.

The trim is made with a stack of varying width, 0.040" thick styrene stock. After gluing the stack, I notched the ends staggering up to the top piece at 0.040" increments and cut each level with the micro razor saw. I spent some time sanding off the remains of the support legs that typify 3D printed parts using the aluminum sanding block from my Precision Sander. The resin sands fairly easy.

After sanding I stuck all the 3D parts onto masking tape turned back on itself and first sprayed it Rattle Can Tamiya White Primer, and then airbrushed with Tamiya Flat White. The long white piece is the "concrete" foundation trim that extends from the end of the right side lower sill to the building's rear. The top and ends are chamfered 45 degrees.

I couldn't help but to try the 3D parts on the wall. They look brilliant!

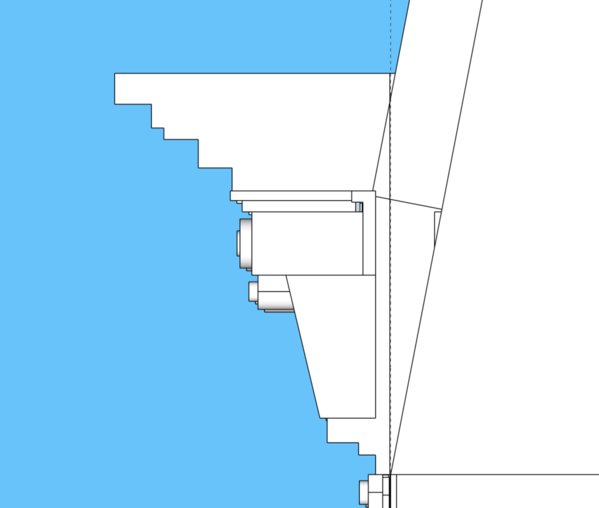

Now for the really cool stuff… The dentil molding sits within a nest of many pieces of styrene to build it out to the building's design. The special widths of many of the wider parts necessitated me to cut it from large 0.040" sheet (about 2" in 1:1 scale).

I often use angle blocks as a backstop to keep pieces that need to be even on one edge in place while gluing. Even with this aide, parts can move and I needed to check alignment before glue dried. Since the dentil molding is resin, it must be glued with CA. I did have to break a joint since it got out of alignment.

I got about 1/2 done on the building front molding. There is a pile of strips that have to go on beyond what you see here. Then there's little round trim pieces that go under each corbel to finish it out. All in all, it's a lot of trim. The extensions out of the right end are because this needs to be mitered to the right side's trim. I was proud of myself that I thought of this before cutting everything too short.

Here's the cross-section that needs to be created. There are five pieces in the top stack with a thinner strip in the number 3 position from the bottom. Again, I'm constrained by the thicknesses and widths offered by Evergreen plus cutting the widest pieces out of a large sheet.

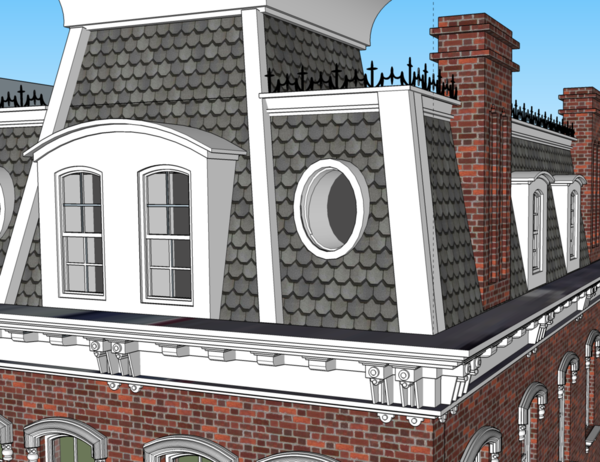

This detail view is from the original drawing with the two chimneys. There's more stacked trim at the roof edge, and still more complicated layers at the store front. The lower trim only extends over the display windows (thankfully…), since the longer the trim to be glued up, the greater the chance for misalignment and twisting. In looking at the below image, I'm realizing that forming the curved roofs on the gables will be challenging too. This is not a building project for the faint-hearted. I'm also thinking that the roof edge trim should be hollowed out since it's actually serving as a rain gutter also.

I cleaned up the oval window 3D print and tried them in the laser cut holes. Fits like a glove! Would have been a bear to scratch build.

Tomorrow, molding work will continue… I expect, by the end of the week, I'll have the rest of the windows done too.