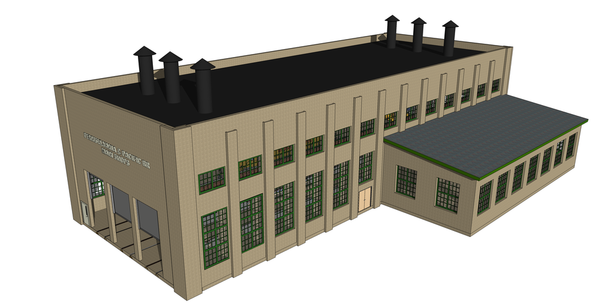

I got a quote to cut the engine house windows that's not out of line. I'm still refining the building itself and pretty much have it finalized.

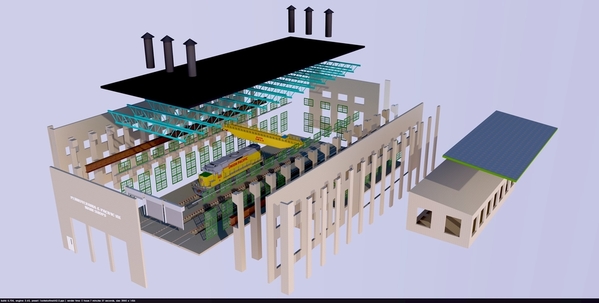

I posted this just a minute ago on another thread dealing specifically with Engine Houses, but I'll show it again here. I made an exploded drawing of the whole deal showing the inner and outer buttresses. The outers are just simple wood strips, but the inners have more structure to support the roof trusses and the large I-beam holding the gantry track. The inners will probably be a hodge podge of laser cut strips and conventionally cut lumber to bulk them up.

I anyone has suggestions on building those inner buttresses that won't break the bank, I'm interested. As it is it's going to be another expensive project. I've offered to do drawings for others if you'd like it in a different length and track spacing. I'm stuck with the 3.5" spacing resulting from using Ross #4 yard ladders.

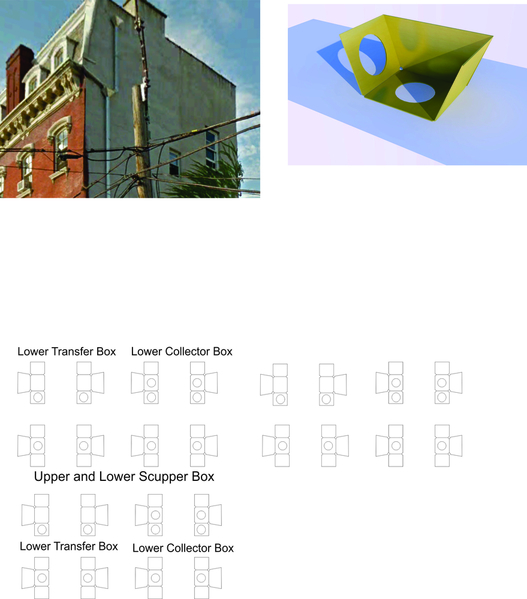

Now back to the Bronx… I installed all the Mansard windows and chimney. Started putting in the 1/4 round molding and began putting in the age weather stripping. I did draw up more specific plans to cut the brass for the downspout system. I first drew a tapered box in SketchUp and actually bent the pieces into position to see if they were correct. I did have to make some minor changes to get this right. I also made the side opening slightly oval since the pipe will be entering straight into a tapered surface. The real ones are tapered in two directions forming a square funnel. I chose to go a bit simpler just tapering in one direction. No one will care...

I didn't cut them out today, but instead got back to all the gable installation. Before I did that, I sanded the erroneous scupper hole filler and repainted the blemishes with the Antique White.

Before installing, the gables needed roofing. I painted some of my very-diminished stock of the Bar Mills "tar paper" roofing some Nato black and applied it to each gable.

The first window in was the front double gable and the oval windows. I used a combination of Aleen's and CA for this. I then cut and installed the 1/4 round molding to trim out the bottom edge. I then installed the four side gables. The front one fit too tightly and was distorting the bottom of the window frame. I finally removed it and shaved a smidgen off the bottom third of the opening on both sides. That corrected the problem. The rest of them went in with less trouble. The chimney was glued to the sub-roof and then tacked where the back touched that reinforcing bar that connects both side Mansard pieces together. Finally I started applying the pre-aged copper flashing and was very happy with the result.

Here's a chimney closeup. I first added some step-cut copper to the chimney before installing, but it really didn't help cover the gap. So I ended up putting a wider piece that covers both sides of the joint. If you closely I've put some over the front gable. This will be repeated on all the others to cover that large gap. I still have to use the 1/4 round on the side Mansard.

I need to put some parapet capping on the as one of the roof detailing tasks. I've entertained thoughts about resin casting some scale terra-cotta styled caps that would be appropriate for building of this age. I can sculpt the master in Super-Sculpey and the make a silicone mold and go to town. The only problem is if I make only one master, molding takes about 1/2 per piece. I'll need about 20 pieces (guesstimate) so you're looking at 10 hours of molding time. It would look very cool though...

I could probably be done this building by the end of the week if… I didn't have two PT appts. to keep working on my lower back. So let's say that completion day will be the end of next week. Hmmm…. as I'm writing that I may be forgetting that just because the building proper is done, doesn't mean the project is. I still have to create the baseboard, the parking lot next door, the signage for said parking lot, any lighting and that wall of ivy. So let's let completion date float a bit.