Thanks guys!

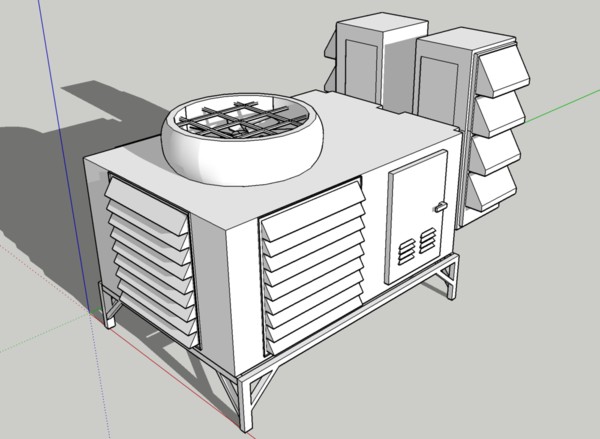

Today I was wrestling with the 3D Printer. I'm breaking the AC project into smaller pieces to improve printing success. Here's the entire unit. Remember, the main driver of print time is the number of layers = height so shorter pieces print faster.

I did get a perfect print of the intake section of the roof AC units that I'm going to print for the Engine House. All the surfaces were flat and edges perfectly square.

I was having trouble with the touch panel with the touch points being significantly out of registration (almost 1/4" low). It was so low that icons on the bottom row were not responding at all. I contacted the company in China via eMail and they sent me a link to a downloadable file that could be used to calibrate the touch pad. They said if it didn't work they would send me a new pad.

After fussing with it, I determined that the touch pad was, indeed, defective and asked them to execute Plan B. It will take between 5 and 12 days to get a new one. I don't know why this one failed.

Meanwhile, I can print because the print and file controls are accessible although out of position. I then attempted printing the main AC unit. Yesterday I tried with the legs down and it failed. Today I re-sliced it so the fan was facing down and the legs up. This made a huge flat surface that had to be held by all the supports. They didn't! The fan printed, but the flat surface disengaged and was stuck on the bottom teflon window. I had to scrape it off and it damaged the surface enough so I have to replace it. My supply of bulk FEP film arrived just in time from McMaster-Carr.

I'm going to redesign the AC so the fan will print sepeartely, and then I'll print the body on a bias. I can see why angling is better since it narrows the cross-section of material that has to be constantly pulled away from the teflon. There's a lot of variables at work here.

Meanwhile, the four walls of the engine house are fully glued. I then permanently added one 3/4" square cross brace to keep the walls aligned properly. I then also added some corner braces since the size of the building made it still a little too flexible for my liking.

I removed about 3/32" from the length of the roof so it now is a nice slip-fit into the building. I put the whole deal onto the floor plate and found to my dismay that the floor is too short by too much to fudge. I'm going to have to fix this since there's nothing anchoring the thin separaters between the doors. I'm also thinking that the floor actually doesn't need to be glued to the walls. The building is heavy enough to hold itself in place without gluing it. I'm also concerned about the flexibility of the middle floor pieces. They're 40" long, only a few inches wide and how now cross bracing in the middle since the tracks interfere with doing so. But… if I don't glue the floor into the building there will be no way to secure those front verticals.

I also added some roof stops to the machine shop roof so it's removable and I can inside easily to add the machines as I print them.

I traced the inner machine shop walls to the roof, glued the pieces in place, and then put the building back on it again and carefully slid the stops up against the walls so they were properly placed.

I then removed the building and weighed down the pieces so they dried.

I did get a successful print of the first smoke jack. I made it so the conical top was actually connected and open to the pipe. In the act of shaking it to get rid of the excess alcohol, I broke off the top. It seems that even though the printer can print anything, it still responds to the laws of physics. My supports connecting the cone to the pipe were just too tiny and not attached to enough meat on the tube. I redrew and re-sliced it and will print it again.