Alan, place them at a 45 degree angle to minimize the adhesion forces on the FEP surface. When at all possible don't print large surfaces parallel to the platen. You're asking for trouble. I had a complete failure on the welding table. I went back and really looked at the drawing and found that the original artist had fully details scale casters including foot locks. I went back and solidified them and got rid of those ridiculous details would be invisible. I then found that the frame memnbers were drawn as hollow square steel tubing. While this is correct, it meant that the printer was creating part that were hollow with a wall thickness of maybe 0.001". No wonder everything before the table wasn't there. I've revised it completely and solidified everything. Rotate them so the widest surface is being held by most of the supports.

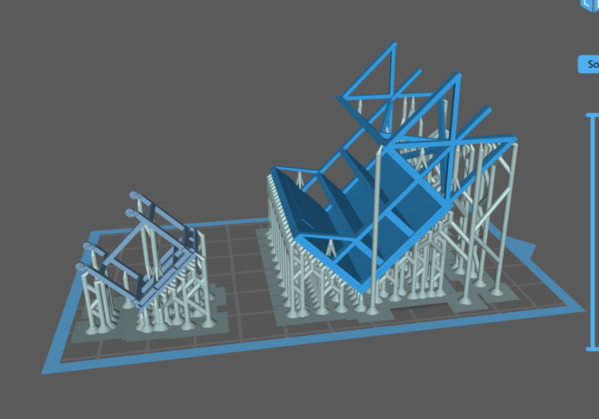

I just set this up on the slicer. I rotated them -135 degrees. I also didn't want a lot of supports in places where they were hard to remove. It's funny, but after hardening for four minutes, those spindly legs on that first workbench print are able to hold it up. Regardless, I beefed up the whole design and made the shelves solid.